Aluminum dross machine delivery for Indian customer

Aluminum dross machine delivery for Indian customer

Aluminum dross machine delivery for Indian customer

Dated on 19th October 2023, the loading of 2 sets of 130 aluminum dross machines was completed for the customer from West Bengal of India. The destination port is Calcutta port of India.

Your continuous support is always appreciated. Our GOD. They bought a total of 7 sets of aluminum dross machines from us from 2010.

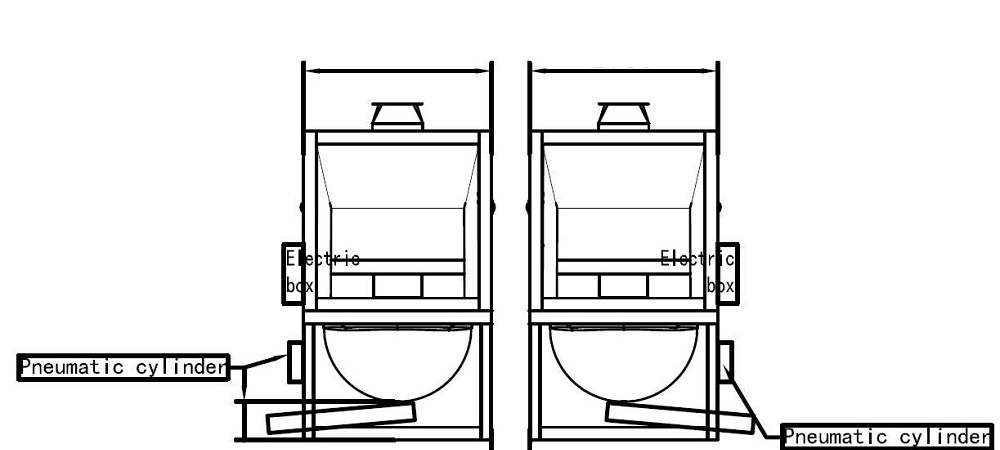

For these 2 sets of aluminum dross machines, the design is made according to the customer’s situation. It is operated by the pneumatic cylinder for the dross outlet, both of them work with the dross cooling and ball mill machine.

Aluminum dross machine is mainly applied for the treatment of high-temperature aluminum dross generated from the furnace.

The aluminum dross machine includes the frame, guard plate, heatproof pot, shaft, stirrer, transmission, reducer and motor main parts.

The function of aluminum dross machine is to recover the metal aluminum from hot aluminum dross, reduce the loss and reduce material costs, and increase the profit.

This machine is applied to separate aluminum from aluminum dross generated in the production process of the furnaces, so that the aluminum metal content in the aluminum dross is reduced from 40-60% to less than 5%.

Compared with the cold processing method of aluminum dross, this machine has the advantages of less metal burning loss, energy saving and environmental protection, a short production process and less equipment investment.

The working principle of the aluminum dross machine is to increase the temperature of high-temperature aluminum dross evenly by stirring and to make the aluminum dross move to generate friction through stirring and moving, destroying the oxide film coated on the outside of the aluminum liquid, so that the aluminum liquid is collected and recovered.

The dross stirring system is the core of the whole set of equipment, which undertakes the tasks of heating up the aluminum dross and separating the aluminum from the aluminum dross.

The reason why the aluminum dross machine is widely used in the aluminum industry, especially the production and processing industry mainly based on aluminum raw materials.

It can indeed play a better use advantage, reduce the loss of metal aluminum, and play a better role in energy saving and environmental protection.

1. The main reason why the aluminum dross machine is widely used is it can extract more than 90% aluminum from hot dross, increase recovery rate, reduce burning loss and increase profit margins

2. Aluminum dross machine is durable, has a longer service life, achieves better standards in terms of application cost and performance, and makes the application process safer, which simplifies the production and processing process.

3. The failure rate is relatively low, no special maintenance and maintenance are required, and the performance is fully guaranteed, allowing the metal recovery rate to reach a higher standard.

4. Aluminum dross machine equipment occupies a relatively small space and the investment is not very high, so all manufacturers who use aluminum scraps as raw materials can choose to use this machine.

5. The frame plays a supporting role, in order to facilitate maintenance and transportation and container loading, the top and bottom separate structures are adopted.

It is easy to arrange transportation and make installation and maintenance.

Brightstar Aluminum Machinery offers a wide solution for aluminum dross processing and recycling.

The solution includes hot dross extraction, separating and recovery as well as dross cooling, crushing, grinding and sieving.

Contact us now to obtain a reliable no-obligation quote for your aluminium dross machine!