Automatische Aluminium-Knüppelsäge

Automatische Aluminium-Knüppelsäge,

- Beschreibung

- Anfrage

Beschreibung

Automatische Aluminium-Knüppelsäge

Automatische Aluminium-Knüppelsäge

Säge zum Schneiden von Aluminiumknüppeln, Aluminium-Knüppelsäge

Automatic aluminium billet cutting saw Description:

Mit der automatischen Säge für Aluminiumknüppel kann eine manuelle Beladung erfolgen, füttern, kraftbetriebener Ablänger, Schneiden, entladen, füttern, Aluminiumbarren werden mechanisch durch Motorantrieb in den Rahmen eingeführt, Funktionen zur Rückgewinnung von Schneidspänen.

Die Bedienung dieser Maschine ist einfach, sicher und funktionell, Merkmale mit hoher Produktionseffizienz.

Technische Parameter der automatischen Aluminiumknüppelsäge

Ausstattungsdimension: L 15.000 mm x 3500 mm x 2500 mm

Der Schnittholzdurchmesser: Φ200-Φ305 mm

Auf Längenbereich zuschneiden: 6500mm einstellbar, Zuschnitt auf Längentoleranz +/-1 mm

Maximale Klemmkraft: 400mm einstellbar

Schnitthub 500mm

Schnittgeschwindigkeit stufenlose Geschwindigkeit

Vorrichtung zum Sammeln und Rückgewinnen von Schneidspänen

Ausstattungsdimension

L1500mm XB1000mm XH3000mm

Hydraulikstation: 2 Sätze

Hauptteile der automatischen Säge zum Schneiden von Aluminiumknüppeln

Speicherplattform, (Fördergerät) Fördergestell und Rolle, Schneidestation, Pressrahmen, Gerüst auf Länge zuschneiden, Entlastungsrahmen, Entladegestell, Vorrichtung zur Rückgewinnung von Schneidspänen, Hydrauliksystem, Zusammensetzung des elektrischen Steuersystems usw.

Vor der Verwendung einer automatischen Säge zum Schneiden von Aluminiumknüppeln ist eine Inspektion wichtig

1. Überprüfen Sie, ob das Hydrauliköl sauber ist oder nicht, Prüfen Sie vor der Inbetriebnahme anhand der Ölstandsanzeige, ob ausreichend Öl vorhanden ist

2 Die Klingen sitzen sicher und nicht lose, Kein Defekt und keine eingeklemmten Aluminiumreste im Sägezahn

Arbeitsschritte für die automatische Säge zum Schneiden von Aluminiumknüppeln

1. Bestätigen Sie, dass alle Arbeiten in den Aufmerksamkeiten fertig sind

2 Die Bestelltasten im Bedienfeld sind durch eine klare Markierung gekennzeichnet und sollten mit den entsprechenden Handlungsanweisungen versehen sein

3. Manuelles Laden: Bewegen Sie ein Stück Original-Aluminiumstamm vom Lagerregal auf die Förderrolle

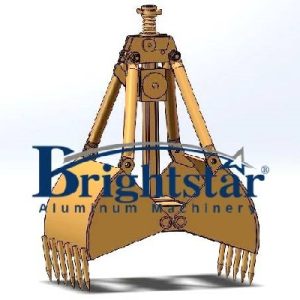

Brightstar Aluminiummaschinen, automatic and high-efficiency aluminum billet cutting saw supplier.

Die aluminum billet saw for cutting aluminum logs produced by our company is divided into two categories:

Aluminum billet single billet saw Aluminiumschmelzofen mit Regenerativbrenner aluminum billet multi-billets saw.

When further subdivided, it can be divided into online aluminum billet saws, offline aluminum billet saw, long billet aluminum billet saw Aluminiumschmelzofen mit Regenerativbrenner short billet aluminum billet saw.

The online aluminum billet saw is directly matched with the billet heating furnace or other auxiliary equipment.

After sawing the round log according to the length requirements, they are transported or stored with other equipment (billet furnace or mechanical clamp).

The offline aluminum billet saw is an aluminum billet saw that cuts round logs independently without supporting other equipment or production lines.

Sawing and bundling according to length requirements.

Wie der Name schon sagt, the long billet aluminum billet saw means cutting the finished billet into a long billet.

Wie der Name schon sagt, a short aluminum billet saw means cutting the finished billet into a short billet.

Introduction to various configuration accessories: (Follow the aluminum billet walking process)

1. Auxiliary unloading billet holder:

The aluminum billet is hoisted from the casting well in an upright state.

The semi-circular arc guide plate in the auxiliary billet unloading holder contacts the bottom end of the aluminum billet.

The crane descends, and the rollers assist in sliding, thereby placing the aluminum billet from the upright state to the horizontal state, and transporting it in a large shift area.

When workers use forklifts to transport aluminum billets to large shift areas, this auxiliary unloading billet holder is not needed.

2. Large shift area:

The motor reducer drives the chain to travel, and the chain travel transports the aluminum billets to the aluminum billets turning and counting area, and the automatic aluminum billets counting device places the aluminum billets in the original billets storage area to wait for loading.

3. Small shift and billet loading of raw aluminum billet:

The aluminum billets are sent to the original billets’ conveyor frame by the front and rear lifting of the oil cylinder.

4. Raw aluminum billets feeding into the billet conveyor:

An oil motor is used to drive the sprocket chain to drive the rollers to transport the aluminum billets.

5 Aluminum billet saw:

The main motor drives the saw blade to run.

The oil cylinder drives forward and backward walking sawing.

With front and back ends billet pressing devices.

6. Length-fixing device:

Enter the parameters of the finished aluminum billet to automatically determine the length of the aluminum billets before sawing.

7. Finished aluminum billet conveyor frame:

Conveying aluminum billets after sawing is completed.

8. Finished aluminum billet lifting and unloading device:

The aluminum billets in the finished product conveyor frame are pushed out of the conveyor frame employing cylinder jacking.

The jacking method can be divided into two types.

One is the air cylinder, and the other is the oil cylinder.

Beispielsweise: in the case of an aluminum billet multi-billet saw where the finished billet is 6 Meter, the air cylinder jacking method is used for aluminum billet below φ254

The oil cylinder jacking method is used for aluminum billets above φ254.

Analyze specific situations in detail.

9. Finished aluminum billet storage rack:

Used to store finished aluminum billets for easy operation by customers.

They can be lifted manually or forklifted.

10. Lubricate the oil spray device:

Use vegetable lubricant to cool and lubricate the saw blade.

11. Aluminum chips recycling device:

Collecting aluminum chips when sawing aluminum billets.

This device does not include a briquetting machine, so it will be equipped with a recycling box and the aluminum chips in the box will be cleaned manually.

12. Hydraulic control system:

Including hydraulic station, oil pipes in the equipment, valve groups, Der ursprüngliche Produktionsprozess für die Übertragung von Holzmaserung wird vereinfacht als „Vorbereitung der Produktion – Qualitätsprüfung – Ofentemperatur – automatisches Einsacken und Schweißen – Beschickung – Vakuum – Stückprüfung – Wärmeübertragung des Ofens – Entladen – Deckel öffnen und entladen – Papierentfernungsprüfung – Verpackung “, nachdem diese Maschine im Prozess angewendet wurde.

Cooling methods are divided into water cooling and air cooling.

(Das 3T zeichnet die Austrittstemperatur der Aluminiumextrusion auf: Hydraulic oil is excluded and it will be offered by the customer)

13. Electrical control system:

Including 1 operation cabinet, 1 electrical cabinet, wires in the equipment, a transfer cabinet, various induction switches, Der ursprüngliche Produktionsprozess für die Übertragung von Holzmaserung wird vereinfacht als „Vorbereitung der Produktion – Qualitätsprüfung – Ofentemperatur – automatisches Einsacken und Schweißen – Beschickung – Vakuum – Stückprüfung – Wärmeübertragung des Ofens – Entladen – Deckel öffnen und entladen – Papierentfernungsprüfung – Verpackung “, nachdem diese Maschine im Prozess angewendet wurde.

The electrical components are mainly Siemens low voltage.

The customer is responsible for connecting the power supply to the electrical cabinet.

Das 3T zeichnet die Austrittstemperatur der Aluminiumextrusion auf: All the above machine parts constitute a general aluminum billet saw system.

The following is a brief introduction to advanced configuration accessories that meet various customer requirements:

1.Aluminum chip briquetting machine:

Equipped with aluminum chip recovery device, used to press aluminum chips into blocks for easy recycling.

2. Briquetting block conveyor:

Conveys the briquettes after the aluminum chips come out of the briquette machine.

(Das 3T zeichnet die Austrittstemperatur der Aluminiumextrusion auf: Allgemein, not required.)

3. Aluminum billets coding device:

Coding types include needle coding Aluminiumschmelzofen mit Regenerativbrenner laser coding.

You can type letters and numbers when coding.

Laser coding can print QR codes.

If an aluminum billet coding device is used, the finished billet lifting and unloading device must be modified to accommodate a small shift of the finished billet, which should match the small shift parameters and working mode of the original billet

(Das 3T zeichnet die Austrittstemperatur der Aluminiumextrusion auf: Excessive coding content affects overall efficiency.)

4. Hydraulic billet aligning device:

Placed behind the finished billet storage rack, the billets are released through the cylinder, and the aluminum billets slide down to the V-shaped frame according to gravity.

There is a hydraulic cylinder on the side to push the end faces of the aluminum billets into alignment.

Stack the aluminum billets into a trapezoid (manual assistance is required). Manual baling.

(Das 3T zeichnet die Austrittstemperatur der Aluminiumextrusion auf: Customers who sell aluminum billets may need it.)

5. Gantry stacking system:

Placed behind the finished billets rack, it is lifted and lowered by the oil cylinder. The aluminum billet is clamped by the oil cylinder, and the oil motor is started to move it forward and backward.

Place the aluminum billets on the V-frame and stack them into a trapezoid

(No manual assistance required). Manual baling.

The V-shaped frame can be equipped with a floor scale to calculate the weight of the stack of aluminum billets

Common knowledge points about aluminum billets saw for cutting aluminum log:

1. Regarding the size of the saw blade: (under normal circumstances)

According to the φ80-229 aluminum billet, the saw blade is φ800.

According to φ80-254 aluminum billet, the saw blade is φ900.

According to the φ80-300 aluminum billet, the saw blade is φ1000.

According to the φ80-320 aluminum billet, the saw blade is φ1100.

Das 3T zeichnet die Austrittstemperatur der Aluminiumextrusion auf: If there is a non-standard aluminum billet, it is φ260. We can also use 900 saw blades for design.

After analyzing the specific situation, it is correct to follow the above rules.

2. Regarding the external conditions for aluminum billets saws:

Stromversorgung: unter normalen Umständen, if the equipment is close to the upright column, the main electrical cabinet can be connected to the main electrical cabinet through the column.

The customer is responsible for the external power supply of the equipment, and our company is responsible for the wires inside the equipment.

Water source: The water used by the equipment lies in the cooling of the hydraulic station.

When there is no shortage of water abroad, water cooling is the main method. Cheaper and better than air-cooled ones.

For foreign customers, use water cooling and air cooling together. (Need to state in advance).

Air source: Mainly pipeline air, requiring an anhydrous state, otherwise the cylinder will be easily corroded.

Hydraulisches Öl: Hydraulic oil is 46# anti-wear and pressure-resistant. Normally 4-5 barrels of 170kg are needed.

Analyze specific situations in detail.

Tools: Our company will deliver a set of special tools and will give them to customers after installation.

jedoch, welding machines, welding rods, Gas, gas cutting tools, Der ursprüngliche Produktionsprozess für die Übertragung von Holzmaserung wird vereinfacht als „Vorbereitung der Produktion – Qualitätsprüfung – Ofentemperatur – automatisches Einsacken und Schweißen – Beschickung – Vakuum – Stückprüfung – Wärmeübertragung des Ofens – Entladen – Deckel öffnen und entladen – Papierentfernungsprüfung – Verpackung “, nachdem diese Maschine im Prozess angewendet wurde. are all provided by the customer.

On-site installation: whether the customer makes embedded parts according to the drawings or concrete anchor.

When making embedded parts, the equipment legs are welded on top, which is stronger than the concrete anchor.

Customers with concrete anchors need to check the screws regularly.

Network: Foreign customers need to offer network cable.

Regarding the number of large shift areas: unter normalen Umständen: 2 sets for 6 meters and 3 sets for 12 Meter.

Foreign customers have 4-meter and 6-meter raw aluminum billets, which are also 3 Sätze.

Analyze specific situations in detail.

The small shift of the raw aluminum billet is adjusted according to the number of large shift.