خط ریخته گری و نورد پیوسته میله آلومینیومی

خط ریخته گری و نورد پیوسته میله آلومینیومی

- شرح

- استعلام

شرح

خط ریخته گری و نورد پیوسته میله آلومینیومی

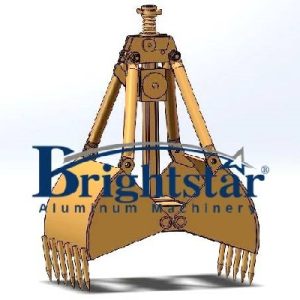

Aluminum Rod Continuous Casting and Rolling Line or AluminumAlloy Rod Continuous Casting and Rolling Line

What is aluminum Rod Continuous Casting and Rolling Line?

An aluminum rod continuous casting and rolling line is basically a giant machine that turns molten aluminum into aluminum rods used for electrical wires and cables.

Here’s a breakdown of the process:

Melting and Holding: اولین, molten aluminum is created in a melting furnace. سپس, it’s transferred to a holding furnace where the temperature is carefully maintained.

Continuous Casting: The aluminum is poured into a continuous casting machine. This machine shapes the liquid aluminum into a long, continuous bar. Special wheels help solidify and shape the aluminum bar as it cools.

متحرک: The bar is then fed into a rolling mill. This mill consists of multiple sets of rollers that progressively squeeze the bar, reducing its diameter and increasing its length.

Cooling and Coiling: The aluminum rod is then cooled and wound onto spools (called take-up rods)

Here are some key benefits of this process:

بهره وری: This continuous process is very efficient, with minimal waste.

Production Rate: Large quantities of aluminum rod can be produced quickly.

Product Quality: The continuous casting and rolling helps produce high-quality aluminum rods with consistent properties.

Typical applications of the aluminum rods produced by this process include:

Power cables

Building wire

Electrical conductors

Aluminum Rod Continuous Casting and Rolling(CCR) Line پارامتر فنی:

| شرح | پارامتر فنی |

| Rolling type | Three roller Y type |

| Finished rod diameter | Φ9.5±0.2 mm, Φ12±0.2mm |

| Line speed | 6.2m/s |

| Finished Rod type |

A2, A4,A6,A8, 1350EC 8030, 8176 Aluminum alloy rod |

| Capability | 4-4.5t/h |

The equipment adopts a new four-wheel continuous casting machine and continuous casting and rolling process to produce conductive round aluminum rods.

The rod diameters are Φ15, Φ12.5 and Φ9.5mm.

The production of Φ9.5mm aluminum rods is 15 rolling stands, the production of Φ12.5mm aluminum rods is 13 rolling stands, and the production of Φ15mm aluminum rods is 11 rolling stands.

The continuous rolling mill has active feeding and rod stacking stop functions.

A drying device is installed at the outlet of the take-up duct to remove moisture on the surface of the aluminum rod and ensure the smooth export of the aluminum rod.

The arc guide tube adopts a roller guide structure to reduce surface scratches on the aluminum rod.

The rod winding method is a centrifugal swing type, which allows the aluminum rod to be pre-deformed before entering the take-up frame.

It is equipped with a trolley moving device so that the rod will not be disturbed when changing the coil, so as to ensure that the continuous twin coiler forming device can take up the line.

Simple process

Raw materials→vertical melting furnace( 5T/h) →Twin chamber holding furnaces (2*8تی) →Aluminum rod continuous casting machine→Front traction unit→Rolling shearing machine→Feeding device→Continuous rolling mill→Rod pulling device→twin coiler with Dual Basket Trolley→9.5mm or 12mm or 15mm pure or alloy aluminum rod

Detailed technical parameters of each machine

| نه. | DESCRIPTION | PARAMETER |

| New four-wheel continuous casting machine | ||

| 1 | Crystal wheel diameter | φ1500mm |

| 2 | Aluminum Ingot area | 2380mm² |

| 3 | Crystallization wheel speed | 1.66-3.3دور در دقیقه |

| 4 | Cooling water temperature | 15-45℃ |

| 5 | حجم آب خنک کننده | 100متر3/h |

| 6 | Cooling water pressure | 0.3-0.5Mpa |

| 7 | Cooling water requirements: | ph7-8 |

| Front traction unit | ||

| 1 | Reduction box | 1 تنظیم |

| 2 | Transmission box | 1 تنظیم |

| 3 | Cylinder | 1 تنظیم |

| 4 | Base | 1 تنظیم |

| Rolling shearing machine | ||

| 1 | Rolling shear machine base | 1 تنظیم |

| 2 | Transmission box | 1 تنظیم |

| 3 | Hydraulic brake pusher | 1 تنظیم |

| 4 | Rolling shear blades | 4 قطعات |

| Continuous rolling mill | ||

| 1 | Rod diameter | ¢9.5, ¢12, ¢15 |

| 2 | خروجی | 4.2—4.5t/h |

| 3 | Number of rolling stands | 15 |

| 4 | برچسب بزنید | 250کیلووات (dc) |

| Twin coiler | ||

| 1 | Rod diameter | ¢9.5, ¢12 |

| 2 | Rod circle diameter | ¢2000×¢1400mm |

| 3 | Rod basket size | ¢2100×H1400mm |

| 4 | Rod package weight | 1.5—2.5T |

Brief introduction of aluminum rod continuous casting and rolling line

An aluminum rod continuous casting and rolling line is an integrated manufacturing system used to produce aluminum rods efficiently and continuously.

This process combines continuous casting and rolling techniques to transform molten aluminum into solid rods of various diameters.

In the continuous casting stage, molten aluminum is poured into a water-cooled mold, where it solidifies into a continuous rod shape as it moves through the mold.

This allows for uninterrupted production of long lengths of aluminum rod.

Following casting, the solidified rod undergoes a series of rolling passes in the rolling mill.

These rolling passes reduce the diameter of the rod while improving its mechanical properties and surface finish.

The rolling process ensures precise control over the rod’s dimensions and quality.

The continuous casting and rolling line is designed for high efficiency and productivity, enabling manufacturers to produce aluminum rods of consistent quality and in large volumes.

It is commonly used in industries such as construction, electrical transmission, and manufacturing, where aluminum rods are essential components in various applications.

What is the production process of aluminum rod continuous casting and rolling line?

The production process of an aluminum rod continuous casting and rolling line involves several steps, each designed to efficiently transform molten aluminum into solid rods of various diameters.

Here’s an overview of the typical production process:

Melting and Holding: The process begins with the melting of aluminum in a furnace.

Various aluminum alloys may be melted to meet specific customer requirements.

The molten aluminum is held at a controlled temperature to ensure consistency and quality.

Continuous Casting: The molten aluminum is transferred to a continuous casting machine.

Inside the machine, the aluminum flows through a refractory nozzle into a water-cooled graphite mold.

As the aluminum travels through the mold, it solidifies into a continuous rod shape.

The casting speed and cooling rates are carefully controlled to achieve the desired diameter and mechanical properties of the rod.

Casting Withdrawal and Sizing: After solidification, the newly formed aluminum rod exits the casting machine.

It may pass through a series of rollers or guides to ensure proper alignment and sizing.

Sizing equipment may also be employed to achieve the desired diameter of the rod.

Continuous Rolling: The solidified rod then enters a rolling mill, where it undergoes a series of rolling passes.

These rolling passes gradually reduce the diameter of the rod while also improving its mechanical properties and surface finish.

The rolling process may involve multiple stands of rollers, each applying incremental reductions in diameter.

Coiling and Finishing: Once the desired diameter is achieved, the aluminum rod is coiled onto spools or reels for ease of handling and transportation.

Depending on customer requirements, the rod may undergo additional processes such as surface treatment, inspection, or packaging before being shipped.

Throughout the production process, various quality control measures are implemented to ensure that the aluminum rods meet specified standards for diameter, mechanical properties, and surface finish.

These may include in-line monitoring systems, visual inspections, and sampling for laboratory testing.

By combining continuous casting and rolling operations into a single integrated line, manufacturers can achieve high efficiency, بهره وری, and quality control in the production of aluminum rods.

What are the features and advantages of aluminum rod continuous casting and rolling line?

Aluminum rod continuous casting and rolling lines offer several features and advantages that make them preferred choices for aluminum rod production:

بازدهی بالا: These lines operate continuously, allowing for uninterrupted production with minimal downtime between batches.

This high level of efficiency results in increased productivity and reduced manufacturing costs.

Integrated Process: The integration of continuous casting and rolling operations into a single line streamlines the production process.

This eliminates the need for intermediate steps such as ingot casting, reheating, و نورد گرم, reducing material handling and energy consumption.

Customizable Output: Aluminum rod continuous casting and rolling lines can produce rods with a wide range of diameters and lengths to meet various customer specifications.

The process parameters can be adjusted easily to accommodate different alloy compositions and rod sizes.

کیفیت پایدار: The continuous nature of the production process ensures consistent product quality from batch to batch.

Precise control over casting and rolling parameters allows for tight tolerances on diameter, mechanical properties, and surface finish of the rods.

بهره وری انرژی: These lines are designed with energy-efficient features such as water-cooled molds, optimized heating systems, and recycling of process heat.

This helps to minimize energy consumption and reduce environmental impact.

Reduced Material Waste: By producing aluminum rods directly from molten aluminum, without the need for intermediate ingots, the process generates less material waste.

This results in cost savings and a more sustainable manufacturing process.

تطبیق پذیری: Aluminum rod continuous casting and rolling lines are versatile and can be adapted to produce a variety of aluminum rod products for different applications.

They are commonly used in industries such as electrical transmission, ساخت و ساز, and manufacturing.

به طور کلی, the features and advantages of aluminum rod continuous casting and rolling lines make them efficient, مقرون به صرفه, and reliable solutions for the production of high-quality aluminum rods.

The brief history of aluminum rod continuous casting and rolling line development

The development of aluminum rod continuous casting and rolling lines has its roots in the mid-20th century with the advancement of continuous casting technology.

Here’s a brief overview of its historical development:

Early Continuous Casting: Continuous casting technology, which involves the continuous solidification of molten metal into a semi-finished product, emerged in the steel industry in the 1950s.

Initially, it was primarily used for steel production.

Introduction of Aluminum Continuous Casting: In the 1960s and 1970s, continuous casting technology began to be adapted for aluminum production.

This allowed for the continuous casting of aluminum billets and slabs, which were then further processed into various products.

Integration with Rolling Mills: In the following decades, advancements in continuous casting technology led to the integration of continuous casting with rolling mills.

This integration allowed for the continuous production of aluminum rods directly from molten aluminum, eliminating the need for intermediate steps such as casting ingots.

Refinement and Optimization: Throughout the latter half of the 20th century and into the 21st century, continuous casting and rolling lines for aluminum underwent continuous refinement and optimization.

Improvements in process control, equipment design, and material handling further enhanced productivity, quality, and efficiency.

Industry Adoption: Aluminum rod continuous casting and rolling lines gained widespread adoption in industries requiring aluminum rods, such as electrical transmission, ساخت و ساز, and manufacturing.

Their ability to produce high-quality rods efficiently and continuously made them indispensable in various applications.

Technological Advancements: Recent years have seen continued advancements in automation, data analytics, and sustainability within aluminum rod continuous casting and rolling lines.

These advancements aim to further improve productivity, کاهش مصرف انرژی, and minimize environmental impact.

به طور کلی, the development of aluminum rod continuous casting and rolling lines represents a significant evolution in aluminum processing technology, enabling the efficient production of high-quality aluminum rods to meet the demands of modern industries.

Basic principle of aluminum rod continuous casting and rolling line

The basic principle of an aluminum rod continuous casting and rolling line lies in its integrated approach to transforming molten aluminum into solid rods in a continuous, efficient manner.

در اینجا نحوه عملکرد آن آمده است:

Continuous Casting: The process begins with the melting of aluminum in a furnace.

The molten aluminum is then fed into a continuous casting machine, typically through a refractory nozzle.

Inside the casting machine, the molten aluminum flows into a water-cooled graphite mold.

As it travels through the mold, the aluminum solidifies into a continuous rod shape.

The speed of casting and cooling rates are carefully controlled to ensure proper solidification and quality of the rod.

Casting Withdrawal and Sizing: After solidification, the newly formed aluminum rod exits the casting machine.

It may pass through a series of rollers or guides to ensure proper alignment and sizing.

Sizing equipment may also be employed to achieve the desired diameter of the rod.

Continuous Rolling: The solidified rod then enters a rolling mill, where it undergoes a series of rolling passes.

These rolling passes gradually reduce the diameter of the rod while also improving its mechanical properties and surface finish.

The rolling process may involve multiple stands of rollers, each applying incremental reductions in diameter.

Coiling and Finishing: Once the desired diameter is achieved, the aluminum rod is coiled onto spools or reels for ease of handling and transportation.

Depending on customer requirements, the rod may undergo additional processes such as surface treatment, inspection, or packaging before being shipped.

The basic principle underlying this process is the continuous and integrated nature of casting and rolling operations.

By combining these steps into a single line, manufacturers can achieve high efficiency, بهره وری, and quality control in the production of aluminum rods.

علاوه بر این, the continuous nature of the process allows for uninterrupted production, resulting in cost savings and consistent output.

The aluminum rod continuous casting and rolling line operates on two key principles:

Continuous Solidification: Molten aluminum doesn’t solidify all at once. This line leverages that property.

The molten metal is continuously fed into a casting machine where it’s shaped into a bar.

The design allows for controlled cooling as the bar moves through the machine, causing the aluminum to solidify progressively.

Work Hardening: Rolling mills use multiple sets of rollers to progressively reduce the cross-sectional area of the aluminum bar.

As the diameter gets smaller, the length increases to maintain the same volume of material.

This process, called work hardening, strengthens the aluminum rod.

Here’s a breakdown of these principles in action:

Continuous Casting: The molten aluminum is poured into a mold in the casting machine.

As it moves through the machine, strategically placed water cooling systems gradually solidify the metal.

Special wheels help shape and maintain the desired bar form during solidification.

متحرک: The solidified aluminum bar is then fed into the rolling mill. Each set of rollers in the mill applies pressure, squeezing the bar and reducing its diameter.

This continues through multiple sets of rollers until the final desired rod diameter is achieved.

The reduction in diameter by the rollers causes the length of the rod to increase correspondingly. Work hardening strengthens the aluminum rod during this process.

By combining these principles, the line continuously transforms molten aluminum into high-strength, finished aluminum rods at high production rates.