Ce qui précède sont les facteurs qui affectent la perte d'oxydation dans la fusion de l'aluminium

Ce qui précède sont les facteurs qui affectent la perte d'oxydation dans la fusion de l'aluminium

Ce qui précède sont les facteurs qui affectent la perte d'oxydation dans la fusion de l'aluminium

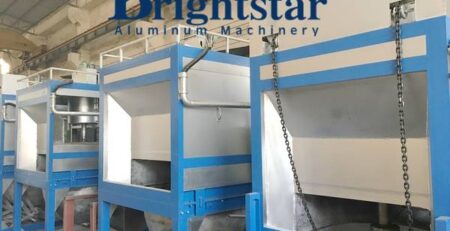

See aluminum dross processing machine working procedure

1. The hot aluminum dross generated from aluminum melting furnace or holding furnace will be skimmed and loaded into the dross trolley;

2. The dross trolley will be moved by the forklift or workers, up to the forklift operation or manual dross trolley;

3. The dross trolley will be lifted by the forklift or the chain lifting system, the dross will be charged into the aluminum dross processing machine pot;

4. Start the stirring fully, the liquid aluminum will go down the launder in the bottom of aluminum dross machine;

5. The liquid aluminum will be cast aluminum ingot in the molds through the discharging device.

Alumina and the impurity will be exhausted by the upper dross discharging port.

The harmful gas and floaters generated in the stirring will be sent to the whirlwind dust collector by air blower.

The exhaust gas will be sent into the air after the water spraying dust elimination purification device, which can meet the requirement of environmental protection.

Main features for aluminum dross processing machine working procedure

*Agitation mécanique, fully stirring, améliorer l'efficacité du travail

*The extraction result is great, improve the aluminum recovery rate

*Adopting whirlwind dust elimination and water spraying dust elimination, the purification of exhaust gas is good, no pollution

*Simple operation, faire que les pièces seront polies grâce à la rotation de la roue de polissage entraînée par le moteur

*No need fuel, make full use of residual heat in hot aluminum dross, profil en aluminium poli et électrophorèse ainsi que profil en aluminium poli et nickelé

*Agitation mécanique, no need flux.