વ્હાઇટ ડ્રોસ અને બ્લેક ડ્રોસ

વ્હાઇટ ડ્રોસ અને બ્લેક ડ્રોસ

વ્હાઇટ ડ્રોસ અને બ્લેક ડ્રોસ

White Dross, what is white dross? white dross definition

White Dross is a mixture of aluminum oxide and aluminum metal with the metal content varying from 15 પ્રતિ 80%.

It is generated during the melting of aluminum in a furnace hearth or the transporting of molten aluminum between furnaces or crucibles.

The dross is collected in a “skimming operation” where an operator either manually removes the floating mixture from the furnace, or in the case of modern large furnaces, an operator on a motorized piece of equipment skims the floating dross.

In either case, the dross mixture is removed from the furnace and into a” skim pan” for containment and cooling.

In addition to the two major dross components, aluminum metal and aluminum oxide, smaller amounts of other compounds can be present depending upon the conditions in the furnace (as well as the subsequent dross pan), the metal source, and the alloys being processed.

These other compounds include aluminum nitride (AlN), એલ્યુમિનિયમ કાર્બાઇડ (Al4C3), and possibly cryolite (Na3AlF6).

The last compound is often associated with molten metal coming from electrolysis cells, while the two former compounds are associated with “thermite” reactions occurring in the furnace or dross skim pan.

White dross can include oxide compounds not directly formed in the furnace such as metallic skim removed from cooled transfer troughs, skulls from crucibles, and spills.

Finally, white dross contains little or no salt flux.

Black Dross, what is black dross? black dross definition

Many aluminum scrap melters use reverberatory furnaces with an external side platform for the charging.

It is a common practice to charge the scrap to the furnace metal pool through this charging way.

The bay often contains a salt flux layer to help protect the molten aluminum pool from oxidation and to improve metal recovery of the scrap.

This type of furnace is especially common when processing light gauge or high surface area scraps such as chips or UBC.

The flux usually consists of sodium chloride (NaCl) and potassium chloride (KCl) with the possible addition of a fluoride salt compound.

A mixture of chloride salts is used to lower the melting point of flux. The flux-containing dross resulting from this melting operation is called “black dross” because of its characteristic dark color.

The black dross consists of a mixture of salt, oxides and metal.

At temperatures above the melting point of the salt flux mixture, the black dross consists of two immiscible liquid phases: aluminum metal and liquid salt containing oxide particles and films.

As the oxide content increases in the salt flux, the mixture becomes less fluid and more viscous in nature.

The flux is very efficient in trapping and holding the oxide compounds.

The metal content of the black dross will vary depending on the scrap type being charged and the processing conditions, but varies from 7 પ્રતિ 35% and in special circumstances as high as 50%.

The oxide content of the black dross will be approximately equal to the salt flux content.

Salt cake, what is salt cake?

Rotary furnace operations processing scraps and drosses use salt flux for the same reasons mentioned earlier, but the ratio of the salt flux to the contained oxide in the resulting by-product is different.

Two modes of operation are common: “wet” and “dry” with the difference being the amount of salt flux added and the rheological consistency of the molten black dross.

In the wet mode, enough salt flux is added to make a liquid pool of molten salt with the approximate consistency of water.

In the dry process, less flux is added and the salt cake has a much drier consistency. The metal content of salt cake is generally lower than that of black dross.

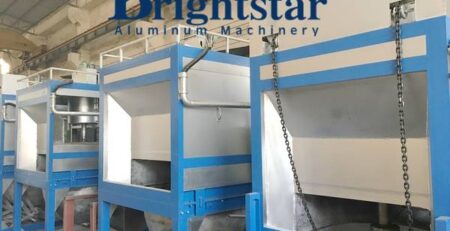

Brightstar એલ્યુમિનિયમ મશીનરી એલ્યુમિનિયમ ડ્રોસ પુનઃપ્રાપ્તિ માટે સંપૂર્ણ ઉકેલ પ્રદાન કરે છે, ટર્નકી પ્રોજેક્ટ અને પેકેજ ડીલ્સ.

નો-ઓબ્લિગેશન ક્વોટ મેળવવા માટે હવે અમારો સંપર્ક કરો એલ્યુમિનિયમ ડ્રોસ મશીન અને એલ્યુમિનિયમ ડ્રોસ પુનઃપ્રાપ્તિ!