एल्यूमीनियम चमकाने मशीन संचालन नियम और रखरखाव

एल्यूमीनियम चमकाने मशीन संचालन नियम और रखरखाव

एल्यूमीनियम चमकाने मशीन संचालन नियम और रखरखाव

एल्यूमीनियम चमकाने मशीन संचालन नियम और रखरखाव

Ⅰ Starting up and ready for work

1. Check the power supply, make sure electric voltage is normal, electrical equipment components are normal, and not out of the way before starting up, start up the dust collector.

2. Rotate the polishing wheel to check the direction of the main shaft movement is correct or not, startup the working table empty running for one circle to check it running smoothly.

3 Open the top cover and pour into the proper liquid wax as there is no air pressure in the pressure tank.

Make sure no leakage for the wax of each pipe, open the main air pipe, and adjust the air pressure and keep 5.5KG-7KG pressure.

4. Adjust the height and length of the workbench positioning sliding block.

The height of the positioning sliding block should be lower than the profile polishing height about 5mm, the length should be longer than profiles about 20mm, which can ensure enough space for thermal expansion elongation coefficient as the aluminum profile is polished.

5. Start polishing wheels, the polishing medium (solid wax) need to be covered on the surface or click the automatic wax spray button as the polishing wheel turn, spray the liquid wax according to the technical effect request.

6. Working table preparation before the operation

Adjust the height between main machine base and profile surface in the workbench, as per motor current for the reference value, the running value is about 20-27A, adjust the working table running speed, the speed is set generally as 10-13m/m (depend on the surface oxide thickness, the thicker oxide thickness, the slower the running speed of workbench).

7. The first group polishing wheel can be started as two polishing wheels contact the profile surface.

Ⅱ Polishing procedure principle

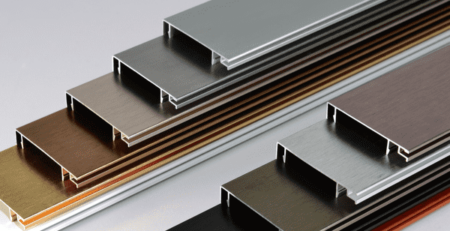

The first time is the primary polishing step, which means the wax will be overlaid evenly on the aluminum profile surface.

The second time is the finish polishing; the cloth wheels will polish the aluminum profile surface overlaid with the wax.

The third time is the mirror polishing procedure; the cloth wheels will clean the wax liquid on the aluminum profile surface after being polished, then the aluminum profile can get the mirror glossy effect.

Ⅲ The working table and aluminum profile unloading

The machine must be stopped when the working table leaves the polishing wheels, अन्यथा, due to the rotation of cloth wheels, that can make aluminum profiles fly out from the working table, which will cause the workers hurt and aluminum profiles damaged.

The operation workers must wear clean gloves, handle with care to avoid the aluminum profile being marked or scratched and damaged.

Ⅳ Mechanical polishing time limit after extrusion and chemical polishing time limit

To avoid unnecessary loss, the aluminum profile that needs to be polished should be polished within 72 hours after the extrusion, and then make the chemical polishing and anodized within 24 hours after mechanical polishing.

Ⅴ Polishing machine maintenance

The dust collector bag needs to be cleaned one time each week.

The machine surface needs to be cleaned with wax solvent one time each month.

The polishing workshop needs to be clean for the dust every day.

All bearings of the polishing machine need to add grease every 10 डेढ़ साल के उपयोग के लिए मशीन ऑर्डर के साथ सकल ट्रॉली के टुकड़े.

The polishing machine adjusting the location column needs to add grease every week.

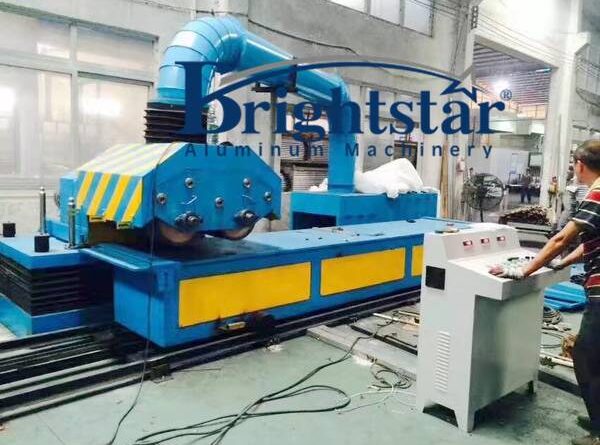

एल्यूमीनियम प्रोफ़ाइल चमकाने मशीन, aluminum extrusion polishing solution provider, ब्राइटस्टार एल्युमिनियम मशीनरी कंपनी, लिमिटेड