एल्यूमिनियम प्रोफाइल पॉलिशिंग मशीन का उपयोग कैसे करें

एल्यूमिनियम प्रोफाइल पॉलिशिंग मशीन का उपयोग कैसे करें

एल्यूमिनियम प्रोफाइल पॉलिशिंग मशीन का उपयोग कैसे करें

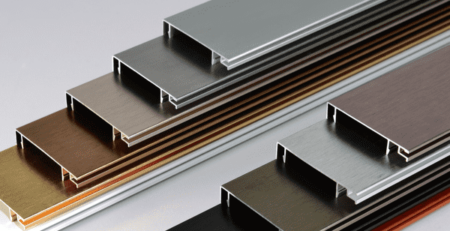

In the world of metal fabrication, एल्यूमीनियम प्रोफाइल आवश्यक घटक हैं.

इन एल्यूमीनियम प्रोफाइलों का उपयोग विभिन्न अनुप्रयोगों में किया जाता है, निर्माण से लेकर ऑटोमोटिव उद्योग तक, उनके हल्के वजन और उच्च शक्ति के कारण.

हालांकि, to ensure these aluminum profiles achieve the desired aesthetic and functional standards, they must be polished to a mirror-like finish.

This is where an एल्यूमीनियम प्रोफ़ाइल चमकाने की मशीन comes into play.

In this comprehensive guide, we’ll delve into how to use aluminum profile polishing machine, ensuring you achieve the best results every time.

Understanding Aluminum Profile Polishing Machines

Before diving into the operational specifics, it’s crucial to understand the basics of these machines.

एक स्वत: एल्यूमीनियम प्रोफ़ाइल चमकाने मशीन is designed to polish and buff aluminum profiles, enhancing their appearance and performance.

These machines come with various features and specifications tailored to meet different polishing needs.

तैयारी: Setting Up the Machine

The first step in using an aluminum profile polishing machine involves the aluminum profile polishing machine setup. Proper setup is vital for ensuring the machine operates efficiently and safely.

1. Choose the Right Location: Place the machine in a well-ventilated area with adequate space around it for easy maneuverability and maintenance.

2. Check Electrical Connections: Ensure the machine is connected to a stable power supply, as fluctuations can affect performance.

3. Inspect the Machine: Before use, check all components for any signs of wear or damage. Replace any worn-out parts as necessary.

Selecting the Polishing Media

Choosing the right polishing media is essential for achieving the desired finish. Polishing media can include different types of abrasives and compounds.

Different Wheels: Depending on the surface condition of the aluminum profile, select the appropriate abrasive wheel. Coarse abrasives are used for initial polishing, while finer abrasives are used for finishing. डेढ़ साल के उपयोग के लिए मशीन ऑर्डर के साथ सकल ट्रॉली के टुकड़े, for aluminum profile mechanical polishing, the cloth and sisal wheels are applied in the production.

Polishing Compounds: These compounds help achieve a high-gloss finish. Different compounds are available for various stages of polishing.

Operating the Aluminum Profile Polishing Machine

समझ how to use aluminum profile polishing machine is crucial for achieving optimal results.

Here’s a step-by-step guide:

Initial Setup: Secure the aluminum profile in the machine’s holder or fixture. Make sure it’s tightly clamped to avoid any movement during polishing.

Adjusting the Speed: Most स्वत: एल्यूमीनियम प्रोफ़ाइल चमकाने मशीन models come with adjustable speed settings. Start with a lower speed for the initial polish and gradually increase it as you progress to finer abrasives.

Polishing Process:

Rough Polishing: Start with a coarse abrasive to remove any surface imperfections. Move the profile slowly and evenly across the abrasive belt or wheel.

Intermediate Polishing: Switch to a medium-grit abrasive to smooth out the surface further.

Final Polishing: Use a fine abrasive and polishing compound to achieve a high-gloss finish.

Monitoring the Process: Continuously monitor the profile to ensure even polishing. Adjust the machine settings as needed to avoid over-polishing or damaging the profile.

Enhancing Efficiency

Aluminum profile polishing machine efficiency is critical for productivity. Here are some tips to enhance efficiency:

1. Regular Maintenance: Keep the machine well-maintained by regularly cleaning and lubricating moving parts. Replace worn-out abrasives and polishing wheels promptly.

2. Optimal Settings: Experiment with different speed and pressure settings to find the optimal balance for your specific polishing needs.

3. Operator Training: Ensure operators are well-trained in using the machine and understand the importance of each step in the polishing process.

Troubleshooting Common Issues

Despite taking all precautions, you may encounter issues during the polishing process. Here are some common problems and their solutions:

1. Uneven Polishing: This can be caused by improper setup or uneven pressure. Ensure the profile is securely clamped and adjust the pressure settings.

2. Surface Damage: Over-polishing or using the wrong abrasive can damage the profile surface. Always start with the recommended abrasive and avoid excessive pressure.

3. Machine Malfunctions: Regularly check for any mechanical issues and consult the manufacturer for repairs or replacement parts.

Sourcing the Right Machine

When it comes to purchasing, it’s crucial to consider reliable aluminum profile polishing machine suppliers.

Here are some factors to consider:

Reputation: Look for suppliers with a proven track record of providing high-quality machines and excellent customer service.

Product Range: Choose a supplier that offers a wide range of machines to meet different polishing needs.

After-Sales Support: Ensure the supplier provides comprehensive after-sales support, including maintenance services and spare parts.

Buying Tips

If you’re looking to buy aluminum profile polishing machine, consider the following tips:

Research: Conduct thorough research to understand the different types of machines available and their features.

Budget: Determine your budget and look for machines that offer the best value for money.

Trial Runs: Whenever possible, request a trial run of the machine to assess its performance before making a purchase.

Advanced Features and Innovations

Modern polishing machines come with advanced features that enhance performance and ease of use. Some of these features include:

स्वचालन: Fully automatic machines reduce the need for manual intervention, improving efficiency and consistency.

Digital Controls: Machines with digital control panels allow for precise adjustments and monitoring of the polishing process.

संरक्षा विशेषताएं: Advanced safety features such as emergency stop buttons and protective enclosures enhance operator safety.

Environmental Considerations

Sustainable practices are becoming increasingly important in the manufacturing industry. When selecting a polishing machine, consider its environmental impact. Look for machines that:

ऊर्जा दक्षता: Choose machines that consume less energy and have a lower carbon footprint.

Waste Management: Opt for machines that include features for managing and recycling waste generated during the polishing process.

Real-World Applications

Polishing aluminum profiles is essential in various industries. Here are some real-world applications:

Automotive: Polished aluminum profiles are used in automotive trim and structural components, enhancing both aesthetics and performance.

निर्माण: In the construction industry, polished aluminum profiles are used in window frames, door frames, and curtain walls for their durability and visual appeal.

Electronics: Polished aluminum profiles are used in the manufacturing of electronic enclosures and heat sinks, providing excellent thermal conductivity and a sleek appearance.

सजावट एल्यूमीनियम प्रोफ़ाइल: polished aluminum tile trim and skirting are used in the floor covering and home improvement, providing a nice and elegant appearance.

Future Trends

The aluminum polishing industry is continuously evolving, with new technologies and trends emerging. Some future trends to watch out for include:

Smart Machines: Integration of IoT and AI in polishing machines for predictive maintenance and optimized performance.

Eco-Friendly Solutions: Development of more sustainable and environmentally friendly polishing processes and materials.

Enhanced Automation: Increased automation and robotics in the polishing process to further improve efficiency and reduce labor costs.

निष्कर्ष

समझ how to use aluminum profile polishing machine is crucial for achieving high-quality finishes and maximizing productivity.

By following the guidelines outlined in this article, you can ensure efficient and effective polishing of aluminum profiles.

Remember to consider factors such as machine setup, polishing media selection, and regular maintenance to optimize the performance of your polishing machine.

Whether you’re looking to buy aluminum profile polishing machine or improve the efficiency of your existing setup, these insights will help you achieve your goals.

Enhancing your aluminum profile polishing machine efficiency not only improves the quality of your finished products but also boosts your overall productivity.

By staying informed about the latest advancements and best practices in the industry, you can ensure that your polishing processes remain at the cutting edge of technology.

सारांश, the right approach to using an aluminum profile polishing machine involves careful preparation, precise operation, and ongoing maintenance.

With the right machine and techniques, you can achieve superior finishes that meet the highest standards of quality and aesthetics in the metal fabrication industry.