How to choose the right aluminum dross machine for your project

How to choose the right aluminum dross machine for your project

How to choose the right aluminum dross machine for your project

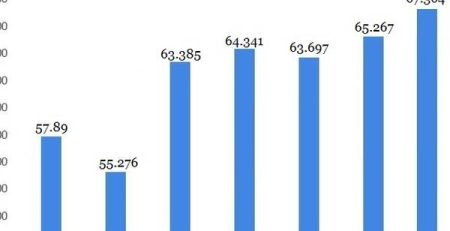

It is reported that the aluminum dross generated in aluminum industry is more than 6 million tons in the world, but only half can be processed to recover aluminum from aluminum dross.

In the past, the aluminum dross recovery method has the following disadvantages

1. Low recovery rate

2. Terrible environmental pollution

3. Heavy working strength, harmful to the health

4. High energy consumption

So, it is necessary to make some changes for aluminum dross recycling

How to choose the right aluminum dross machine for your project?

Typically, Aluminum dross machine is being considered for additional long just before the work begins on the aluminum dross recycling project.

Given the different processing ways of aluminum dross machine available in the market, making a selection of the most appropriate aluminum dross machine can be confusing.

Brightstar Aluminum Machinery offers a few tips on choosing the right aluminum dross machine for your dross recovery project, quick and fast.

If you can get the right aluminum dross machine, the processing cost and the recovery rate will be great, which can do the trick or go through the roof.

If getting the improper dross machine, that will cause low production capacity and bad recovery rate, the worst is cannot use in the production.

Choose the right dross machine for hot or cold aluminum dross

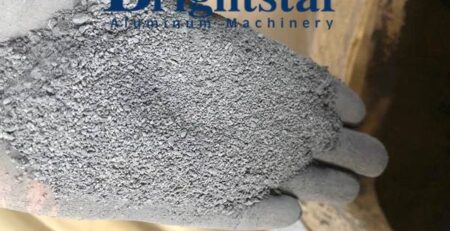

Hot dross, a major by-product of all processes involving molten aluminum, forms at the surface of the molten metal as the latter reacts with the furnace atmosphere.

In general, it is generated from the furnaces and can be recycled directly with an aluminum dross machine.

Cold dross, the product of hot dross after natural cooling or go through the cooling machine, some are processed before the cooling, extract the most aluminum from hot dross, some are not processed before the cooling.

The aluminum dross machine will be different for hot dross or cold dross.

If you are not sure what kind of machine is necessary for your project, you can send us your idea, Brightstar aluminum machinery will provide the professional suggestion for your project based on many years of practice and 136 successful projects.

Choose the right dross machine for processing quantity

As the dross processing quantity is different for the customers, the model of the dross processing machine will be different.

For 100 kgs to 1,000 kgs dross processing quantity per run, or 200kgs to 30,000kgs processing quantity per day, the project solution will be different.

The machines and the system will be different based on the different processing quantities.

Brightstar Aluminum Machinery offers a total solution for dross processing and dross cooling.

Choose the right dross machine for different requests

Some of the customers need the automatic and high efficiency integrated aluminum dross processing system, as the quantity of aluminum dross generated from the furnaces is considerable.

Some of the customers only need simple and cost-effective aluminum dross machine, the quantity of aluminum dross generated from the pit furnace is small, also they need to save the cost.

Some of the customers need heat aluminum dross in the operation and then extract aluminum from hot dross, so the rotary furnace with the burner is necessary for the request.

Some of the customers need to reclaim aluminum from hot dross, then cool it in the operation. As they buy some cold aluminum dross from other suppliers, with their own aluminum dross, ball mill and sieving machine will be set up separately with the hopper for the secondary recycling.

For different requests, the equipment setting and its investment will be different.

Whether you are a startup or a large aluminum industry company, we have the right aluminum dross machine for you.

Talk to the expert

Brightstar Aluminum Machinery offers a wide solution for aluminum dross processing and recycling.

The solution includes hot dross extraction, separating, recovery as well as dross cooling, crushing, grinding and sieving.

Consult with our technical team for the recommendations and advice on the right dross processing operation for your aluminum project and see how to make a profit from them.