അലുമിനിയം സ്ക്രാപ്പ് റീസൈക്ലിംഗ് ഫർണസ്

അലുമിനിയം സ്ക്രാപ്പ് റീസൈക്ലിംഗ് ഫർണസ്

- വിവരണം

- അന്വേഷണം

വിവരണം

അലുമിനിയം സ്ക്രാപ്പ് റീസൈക്ലിംഗ് ഫർണസ്

അലുമിനിയം സ്ക്രാപ്പ് റീസൈക്ലിംഗ് ഫർണസ്

Aluminium scrap recycling furnace design

Raw materials: aluminum scrap

ഉൽപ്പന്നങ്ങൾ: ADC12 alloy

ഉത്പാദന ശേഷി: about 60T/24Hrs/line (3.5 furnaces/day)

Fuel: Heavy oil (Calorific value≥10000Kcal / Kg)

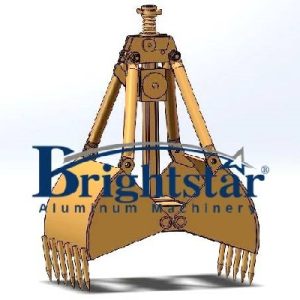

Aluminium scrap recycling furnace group

One set of 16T rectangular regenerative melting furnace

One set of 18T rectangular regenerative holding furnace

One set of charging machine for melting furnace

One set of permanent magnetic stirrer for holding furnace

16T rectangular regenerative melting furnace

The furnace is equipped with a set of electric inclined-pull furnace door, and the specific size is negotiated according to the width of the forklift and the hopper

Equipped with a smoking hood at the door of the furnace and a set of 750W fans;

Equipped with a set of 2.5 million kcal regenerative burner

Function and feature:

1. Adopting high and low double discharge port structures, during normal production, the liquid aluminum is discharged into the holding furnace through the high discharge port.

The solid iron stays at the bottom of melting furnace due to its high density and cannot enter the holding furnace through the high discharge port. This can prevent the molten aluminum from the holding furnace from containing solid iron, causing the iron content in the molten aluminum to exceed the standard.

The low water outlet is used to drain the molten aluminum from the melting furnace when the melting furnace stops production.

The low drain can also be used as an emergency overflow hole when the molten aluminum needs to be transferred out when an accident occurs in the work of the melting furnace.

2. The smelting furnace discharges water to the holding furnace through the high water discharge port. After it is drained, about 0.5-1T of molten aluminum is stored at the bottom of the furnace.

ഇപ്പോൾ, solid iron is pulled out to prevent the molten aluminum from exceeding the standard when the melting continues.

3. Taking away the exhaust gas that is generated in the refining.

4. Initial skimming and refining will be done in melting furnace.

18T rectangular holding furnace

Equipped with a set of electric inclined-pull furnace door

Equipped with one set furnace door smoke hood and 750W fan

Equipped permanent magnetic stirrer in the bottom

Function and feature

1. Taking about 15 Tons liquid aluminum from melting furnace

2. Leave about 20% charging capacity in order to composition adjustment for some other alloy

3. Taking away exhaust gas generated in the refining

4. Refining and skimming, temperature rising, alloying, holding, and casting will be done from the holding furnace

Materials charging

To reduce the burning loss maximally, 3-4 batching charging for 16T melting furnace.

The first charging will be 7-8 Tons big clean aluminum scrap (the less of iron scrap is, the better will be), after it melts to liquid aluminum, we will take the liquid aluminum as the base liquid, then will charge medium-sized scrap (the iron scrap will be much more than the first charging) into the existing liquid aluminum.

It is better to add the amount of solid material to overflow the aluminum liquid. If possible, we can press down solid aluminum scrap into the liquid aluminum through the forklift; Firing to achieve the submerged melting for aluminum scrap.

Charging in the same way for the aluminum scrap melting until it melts 16 T nominal capacity.

The charging orders for aluminum scrap are as the following:

From big to small orders, from big aluminum scrap, medium-sized aluminum scrap, then small aluminum scrap, the purpose is for reducing aluminum scrap burning loss maximally.

The iron content rate order, from low iron content to highest iron content, this purpose is to reduce the stay time of iron maximally in the chamber of a furnace, which can prevent the iron content out of the limit of liquid aluminum.

Iron removal

After 16T melting furnace is full of liquid aluminum, open the high water outlet to transfer the molten aluminum into the holding furnace.

Because the water outlet is slightly higher than the bottom of the furnace, there will be about 0.5-1T of molten aluminum that cannot flow into the holding furnace when the molten aluminum is discharged.

The iron scrap with aluminum raw materials charging in the melting process will stay in this part of aluminum water, which can be easily and conveniently stripped, so as not to increase the iron content in the molten aluminum.

After the iron removal is completed, through observation, if it is considered that the iron has been completely cleared from the melting furnace, then directly charge scrap aluminum to the 0.5-1T aluminum liquid for melting in the second furnace

The solid iron in the melting furnace must be pulled out as much as possible before the next batch of charging and smelting can be carried out.

Technical data of aluminium scrap recycling furnace

|

NO. |

Project | 16T rectangular regenerative melting furnace | 18T rectangular regenerative holding furnace | കുറിപ്പ് |

| 1 | Nominal capacity | 16ടി | 18ടി | |

| 2 | Max capacity | 16T+8% | 18T+8% | |

| 4 | The depth of liquid bath(മി.മീ) | 600+50 | 600+50 |

600 is the average depth 50 is the distance from the layer of liquid to furnace door |

| 5 | Furnace door specification | 1700×1500 | 1700×1500 | Can be set according to the customer request |

| 7 | ബർണർ മോഡൽ | 2.5 million kcal regenerative burner | 2.0 million kcal regenerative burner | |

| 8 | Permant magnetic Stirrer model | ഇല്ല | YC1360 | |

| 9 | Main power of the stirrer | ഇല്ല | 30 KW(Frequency modulation ) | The actual power consumption 8-15Kw |

| 10 | The other power consumption capacity | 37Kw | 29Kw | Not including charging machine and magnetic stirrer |

| NO. | Project | 16T melting furnace | 18T holding furnace | കുറിപ്പ് |

| 1 | Energy consumption(104Kacl/T) | ≤60 |

≤10

|

≤70Kg heavy oil/T.Al |

| 2 | Max melting speed | 5ടി | Excluding charging time | |

| 3 | Normal net burning loss rate | ≤4~7% | The requirement is clean aluminum scrap after sorting, excluding the iron and impurity content, aluminum dross is calculated as 30% | |

| 4 | Magnet window lifetime | ≥2 years | ||