Aluminium dross cooling rotary drum

Aluminium dross cooling rotary drum,

- Description

- Inquiry

Description

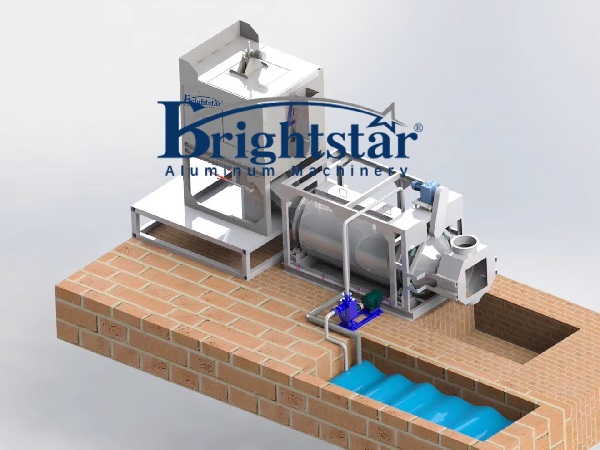

Aluminium dross cooling rotary drum

Aluminium dross cooling rotary drum

Why aluminium dross cooling rotary drum

There will be a lot of aluminum dross generated from aluminum melting, aluminium dross quantity generated in the recycled aluminium industry will be shared 15-20% of feeding materials.

We can extract most of aluminum from hot aluminium dross through aluminium dross machine, but there is still 5%-15% aluminum left in the dross.

Aluminum dross cooling rotary drum can be applied after the dross processing, which can not only cool hot aluminum dross rapidly to normal temperature, but also avoid the burning loss during natural cooling.

The cold dross after the cooling process can be recycled in the melting furnace or rotary furnace.

The cooling process can increase aluminium recovery rate, minimize dust and smoke pollution effectively.

Main part

Cooling rotary drum body, rotary gear, rotary motor, control electric cabinet

Working function

Through rotation of the drum body by the motor drive the gear, the temperature of hot aluminium dross will be lowered quickly when going through the water cooling area, which can get to normal temperature in a short time.

Main technical parameter

Overall size: L 4500mm W2800mm H 1600 mm

Cooling barrel size: φ1100mm L 2500mm

Cooling barrel materials: Thickness 6mm 304 stainless steel

Dross inlet: φ500mm-600mm Dross outlet :φ500mm

Cooling water barrel size: L1300mmX W1250mmX H 230mm

3mm stainless steel materials

Power: 5.5KW

Can be made according to your project.