Aluminum profile surface defects grinding and cleaning machine

Aluminum profile surface defects grinding and cleaning machine

- Description

- Inquiry

Description

Aluminum profile surface defects grinding and cleaning machine

Aluminum profile surface defects grinding and cleaning machine

The function of aluminum profile surface defects grinding and cleaning machine

The main function of this machine is to remove particles, burrs, die lines, marks, scratches, extrusion die lines and surface defects from aluminum profiles, clean the surface of aluminum profiles, improve the brightness of aluminum profiles.

It is the best auxiliary equipment for aluminum profile cleaning and brushing and grinding before anodizing and powder coated and wood grain effect sublimation process.

Minimize or avoid the quality problem and reduce NG rate after anodizing and powder coated process and wood grain effect sublimation process.

It can increase your profit through improve the finished product rate.

Why do we need aluminum profile surface defects grinding and cleaning machine?

In the extrusion production of aluminum profiles, there are some small particles adsorbed on the surface of aluminum profiles in different degrees.

This kind of surface defect only has a slight hand feeling, which is difficult to find without careful observation or touch.

However, it seriously affects the appearance of anodizing, electrophoretic painting and powder coating aluminum profiles, reduces production efficiency and yield, and is a fatal defect of high-end decorative aluminum profiles.

Our machine can be applied before anodizing, powder coating and wood grain effect sublimation process.

It can remove the granular burrs effectively and brighten aluminum profile in high efficiency.

Minimize or avoid the quality problem and reduce NG rate and increase your profit.

In aluminum industry, the production cost has been continuously increased.

The traditional process and outdated equipment cannot meet the needs of factory production anymore.

The manual operation process of aluminum profile surface cleaning and grindingg is time-consuming and labor-intensive, and other processes increase the production cost.

We have developed this automatic aluminum profile surface defects grinding and cleaning equipment, which can better meet the customer’s requirements for surface technology, especially for anodizing, powder-coated process and wood grain effect sublimation surface.

Technical data of aluminum profile surface defects brushing and cleaning machine

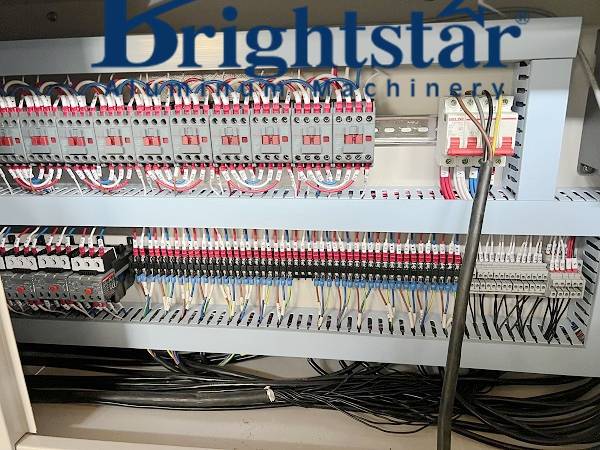

Voltage and HZ: AC 3 phase 5 wires 380V 50HZ, please inform us before the production if it is different

Brush wheel power: 18KW

Regulation power: 6KW

Dust collector power:4KW

Max processing dimension: 150mmX150mm

Main machine overall size: L2020mmXW1200mmXH1700mm

The production line total space: 4500mm(front aluminum profile frame)+2020mm(main machine)+4500mm(back aluminum profile frame)

Total weight: about 1400kgs

What is the difference between aluminum profile surface defects brushing and cleaning machine and aluminum profile polishing machine?

The difference between an aluminum profile surface defects brushing and cleaning machine and an aluminum profile polishing machine lies in their respective functions and the types of surface treatment they provide:

Aluminum Profile Surface Defects Brushing and Cleaning Machine:

Function: This machine is primarily designed to remove surface defects, contaminants, and debris from aluminum profiles.

It typically utilizes brushes, abrasive pads, or other abrasive materials to scrub the surface of the profiles, removing imperfections such as oxidation, stains, dirt, or corrosion.

Process: The brushing and cleaning machine works by mechanically agitating the surface of the aluminum profiles, effectively scrubbing away any defects or contaminants.

This process may involve the use of cleaning agents or water to aid in the removal of stubborn stains or residues.

Result: The main objective of this machine is to prepare the surface of the aluminum profiles for subsequent finishing processes, such as painting, anodizing, or powder coating.

It does not aim to achieve a high-gloss or mirror-like finish but rather to ensure a clean and uniform surface free from defects.

Application: This machine is commonly used in aluminum extrusion plants or manufacturing facilities to prepare profiles for further processing or finishing.

It is particularly useful for removing surface imperfections that may affect the quality or appearance of the final product.

Aluminum Profile Polishing Machine:

Function: Unlike the brushing and cleaning machine, the polishing machine is specifically designed to enhance the aesthetic appearance of aluminum profiles by achieving a smooth, shiny, and reflective surface finish.

It utilizes polishing compounds, buffing wheels, or abrasive belts to mechanically polish the surface of the profiles to a desired level of gloss.

Process: The polishing machine works by mechanically abrading the surface of the aluminum profiles with progressively finer abrasives, gradually smoothing out imperfections and creating a mirror-like finish.

Depending on the desired outcome, different polishing techniques and materials may be employed.

Result: The primary goal of the polishing machine is to achieve a high-quality, decorative finish on the surface of the aluminum profiles.

This can enhance the visual appeal of the profiles and make them suitable for applications where aesthetics are important, such as architectural, automotive, or decorative applications.

Application: Polishing machines are commonly used in industries where high-quality surface finishes are required, such as architectural aluminum fabrication, furniture manufacturing, automotive trim production, and consumer electronics.

In summary, while both machines are used for surface treatment of aluminum profiles, the brushing and cleaning machine focuses on removing defects and contaminants to prepare the surface for further processing, while the polishing machine is dedicated to achieving a smooth, shiny, and reflective finish for decorative or aesthetic purposes.

What is the difference between aluminum profile surface defects brushing and cleaning machine and aluminum profile brushing machine?

The difference between an aluminum profile surface defects brushing and cleaning machine and an aluminum profile brushing machine lies in their specific functions and the extent of surface treatment they provide:

Aluminum Profile Surface Defects Brushing and Cleaning Machine:

Function: An aluminum profile surface defects brushing and cleaning machine, on the other hand, is specifically designed to address surface defects, contaminants, and debris on aluminum profiles.

It aims to clean and prepare the surface of the profiles for further processing or finishing.

Process: This machine typically incorporates brushing or scrubbing mechanisms along with cleaning agents or water jets to remove oxidation, stains, dirt, corrosion, or other imperfections from the surface of the aluminum profiles.

Result: The primary outcome of a surface defects brushing and cleaning machine is to ensure that the aluminum profiles are free from defects and contaminants, providing a clean and uniform surface ready for subsequent processing steps such as anodizing, painting, or powder coating.

Application: Surface defects brushing and cleaning machines are commonly used in aluminum extrusion plants, manufacturing facilities, or finishing shops to prepare profiles for further processing or finishing.

They are particularly useful for removing surface imperfections that may affect the quality or appearance of the final product.

Aluminum Profile Brushing Machine:

Function: A standard aluminum profile brushing machine is primarily designed to brush the surface of aluminum profiles to achieve a uniform texture or finish.

It typically utilizes rotating brushes or abrasive belts to mechanically brush the surface of the profiles.

Process: The brushing machine works by mechanically abrading the surface of the aluminum profiles, creating a consistent texture or grain pattern.

This process may involve the use of different brush types, abrasives, or brush configurations to achieve the desired finish.

Result: The main objective of a brushing machine is to provide a uniform and aesthetically pleasing surface texture on the aluminum profiles.

This may involve brushing to create a matte finish, satin finish, or other textured surfaces, depending on the requirements of the application.

Application: Brushing machines are commonly used in industries where surface aesthetics or texture are important, such as architectural aluminum fabrication, furniture manufacturing, automotive trim production, and industrial applications where a non-reflective finish is desired.

In summary, while both types of machines involve brushing the surface of aluminum profiles, the surface defects brushing and cleaning machine is specifically designed to clean and prepare the surface of the profiles by removing defects and contaminants, while the standard brushing machine focuses on providing a desired texture or hairline finish.