Automatic molten aluminium refining degassing machine

- Description

- Inquiry

Description

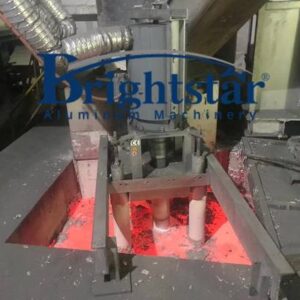

Automatic molten aluminium refining degassing machine

Automatic molten aluminium refining degassing machine

Molten aluminium degassing machine

Molten aluminium refining machine

Automatic molten aluminium refining degassing machine is special equipment designed and manufactured by our company to refine aluminum liquid.

The device is driven by a motor to drive a graphite rotor immersed in a crucible, and high-purity nitrogen gas is feed into the aluminum liquid through a graphite rotor.

The refining agent can be charged to the aluminum liquid through an external powder feeding device.

The aluminum liquid and nitrogen or argon and the refining agent achieve the purpose of degassing and slag removal under the certain rotation of the graphite rotor.

Application

Automatic molten aluminium refining degassing machine is suitable for the refining of aluminum liquid in the crucible, molten pool and transfer ladle.

Applicable furnace diameter Φ200-1700mm, furnace depth 500-1000mm, can also be designed according to the requirements.

The equipment has the advantages of reliable operation, easy operation, easy maintenance, convenient graphite rotor replacement, etc.

It is ideal equipment for aluminum liquid refining in aluminum casting factories.

Degassing principle

Hydrogen has a high solubility in aluminum liquid, which reduces the physical properties and machinability of castings. To cast high-quality castings, the hydrogen content of the aluminum liquid must be kept at a low level.

The small rotor of the degassing refining equipment can effectively disperse the inert gas into small bubbles, which are evenly dispersed and floated in the aluminum liquid.

The partial pressure of hydrogen in the aluminum liquid is higher than that in the bubble, and the hydrogen gas will diffuse into the inert gas and float up to the liquid surface with the bubble, thereby effectively reducing the hydrogen content in the aluminum liquid.

At the same time, the floating bubbles bring the fine inclusions in the aluminum liquid to the surface of the aluminum liquid and are captured and removed by the covering agent.

Technical data

| ITEM | Technical data | Note | |

|

Refining gas |

Purity % | ≥99.996 |

High purity nitrogen or argon |

| Moisture content ppm | ≤ 3 | ||

| O2 ppm | ≤ 5 | ||

| Pressure MPa | 0.1-0.6 adjustable | ||

| Flow m3/h | 0~2.5 adjustable | ||

|

Power supply |

Phase | 3 | |

| Voltage | 415±10% | ||

| Hz | 50 | ||

| Total power kW | < 3 | ||

| Arm lifting motor | KW | 1.1 | Arm lifting |

| Rotating motor | KW | 1.1 | Shaft rotation |

| Baffle lifting motor | KW | 0.2 | Graphite baffle lifting |

| Powder charging motor | KW | 0.2 | Powder charging |

| Graphite rotor rotating speed r/min | 0~600 | Adjustable | |

| Refining degassing time min | 0~99 | Adjustable | |

| Liquid aluminum temperature ℃ | 640-850 | ||

| Processing liquid aluminum quantity kg | ≥300 | One time | |

| Graphite rotation shaft size | Dia Φ | 80 | |

| Length | 750 | ||

| Graphite rotor size | Dia Φ | 180 | |

| Length | 52 | ||

|

Graphite baffle size |

Length mm | 600 | |

| Width mm | 90 | ||

| Thickness mm | 52 | ||

| Quantity | 1 | ||

| Weight kgs | 550-600 | ||

Molten aluminium refining degassing machine and equipment made by Brightstar Aluminum Machinery Co., Ltd.