- Description

- Inquiry

Description

Cable granulator

Cable granulator

The cable granulator, also known as copper wire granulator, it is the copper wire and cable recycling equipment, which is a machine used to crush the copper wires and separate the copper and plastic.

A cable granulator is a machine used for recycling scrap copper wires and cables by granulating (shredding) them and then separating the copper from the plastic insulation.

These machines are particularly valuable in the recycling industry, where they help recover valuable metals from discarded cables, reducing waste and promoting sustainability.

The overall structure of the machine has the advantages of fully automatic crushing, feeding, dust collection, separation, only one person needs to feed the material for production.

Scope of application and function: It is for various automobile circuit wires, motorcycle wires, battery car wires, TV sets, washing machines, refrigerators, air conditioners and other household appliances wires and cables, communication wires, computer wires and other waste lines that are not suitable for processing by various wire stripping machines.

Equipment Introduction

The cable granulator is a production line used to recycle waste copper wires and cables.

It crushes waste wires and cables to obtain copper particles and plastic particles.

The cable recycling production line has a novel design, compact structure, low power consumption and stable performance.

It is mainly used to recycle various waste cables and separate the raw materials into fine copper rice and PVC.

The applicable range is from 0.3 mm to 20 mm wire diameter, such as automotive wires, car bottom wires, motorcycle wires, computer wires and communication cables.

The waste cable and wire granulator has a new and unique structure, large production volume and low power consumption.

Large and small wires can be crushed and separated at the same time without classification, with a high sorting rate, one-time feeding, and multiple machines working together.

The entire line is controlled by PLC and is at the leading level in China.

The successful development of this machine not only solves the problems in the incineration copper extraction method, but also improves the quality of recycled copper, and can recycle plastics, while solving environmental pollution.

The cable granulator is mainly used to recycle various waste cables, separating the raw materials into fine copper wires and PVC.

The applicable range is from 0.3 mm to 20 mm wire diameter, such as automotive wires, car wires, motorcycle wires, computer wires, etc.

Capacity: 100-1000 Kg/H (customization supported)

Sorting rate: more than 98%

Voltage: 380v, 415V, 430V

Raw materials: waste communication wires, automotive wires, computer wires, telephone wires, household appliance wires, etc.

Final products: copper particles, plastic particles

Features of cable granulator

⭐The waste cable and copper wire granulator does not require water, incineration, or chemical reactions throughout the process.

It is sealed and has multi-stage dust filtration and collection, and does not pollute the environment.

⭐Various types of wires do not need to be sorted and can be put into this equipment at the same time.

After crushing, they can automatically separate clean copper and plastic;

⭐ The whole set of equipment adopts a platform combination design.

After the customer receives the machine, he only needs to connect the power and use it, without the need for re-assembly and debugging;

⭐ PLC control, uniform feeding, intelligent operation, can automatically adjust the front-end feeding frequency according to the workload of the back-end, and will not cause the system to shut down due to overload.

The operation is simple, saving time and effort;

⭐The crushing tool is made of high-hardness alloy steel material, which is wear-resistant and impact-resistant, and has a long service life.

⭐Shredding and Granulating System: The machine typically includes a shredder that breaks down cables into smaller pieces, followed by a granulator that further reduces the size of the material into fine granules.

⭐Separation System: Advanced cable granulators use various separation technologies, such as air separation, vibration separation, and electrostatic separation, to efficiently separate copper from plastic insulation.

⭐Dust Collection: Many granulators are equipped with dust collection systems to minimize airborne particles and maintain a clean working environment.

⭐Control Panel: Modern machines often come with a user-friendly control panel for easy operation and monitoring of the granulation process.

⭐Durability and Robust Construction: These machines are typically built with durable materials to handle the tough recycling process and ensure longevity.

⭐Variable Output Size: The granulator may have adjustable screens or settings to produce granules of different sizes according to the requirements.

Advantages of Using Cable Granulators

Efficient Recycling: Cable granulators allow for the efficient recovery of copper and other metals from scrap cables, reducing the need for raw material extraction and conserving natural resources.

Economic Benefits: By recycling cables, businesses can generate revenue from selling the separated copper and other metals, making it a profitable venture.

Environmental Impact: Recycling cables reduces electronic waste and environmental pollution, contributing to a cleaner and more sustainable environment.

Waste Reduction: Cable granulators help reduce the volume of waste that ends up in landfills by converting waste cables into reusable raw materials.

Automation and Ease of Use: Modern cable granulators are automated and designed for easy operation, reducing the need for manual labor and increasing productivity.

High Purity Output: These machines are capable of producing high-purity copper granules, which can be directly reused in various industries.

Versatility: Cable granulators can handle a wide range of cable types and sizes, including household wires, industrial cables, and automotive wiring.

Safety Features: Many granulators are equipped with safety features to protect operators and ensure safe operation, such as emergency stop buttons and protective covers.

Application areas

The fully automatic dry waste cable and wire granulator (waste wire and cable processing equipment) produced by our company is mainly used to recycle various waste communication cables with a diameter of 0.3mm-20mm, automobile and motorcycle circuit wires, household appliances and home decoration wires, waste miscellaneous wires, computer telephone wires, network cables and other hairy and fine wires, as well as various civil wires that are not suitable for processing by wire stripping machines.

Machine and process

Waste communication cables, automobile and motorcycle circuits wires, household appliances and home decoration wires, waste miscellaneous wires, telephone wires and network cables, and various civil wires that are not suitable for processing by wire stripping machines.

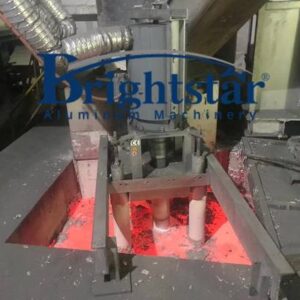

The production line of the fully automatic dry waste cable and wire granulator (waste wire and cable processing equipment) is mainly composed of a shredder, a crusher, an airflow separator, air conveyor, an electrostatic separator, a pulse dust collector, and a PLC centralized control system.

First, a shredder is used to break the material into pieces of about 3 cm in length, and then the material is further crushed by a shearing crusher to peel off the plastic and copper.

The crushed material enters a high-precision airflow separator through an air conveying system for sorting to obtain plastic and copper.

The unsorted plastic enters the electrostatic separator for secondary sorting to ensure the reuse rate of copper.

At the same time, pulse dust collection equipment is used to effectively control dust overflow, and the dust removal efficiency is as high as 99%, ensuring that there is no dust pollution during the production process.

What is a cable granulator used for?

A cable granulator is used for recycling and recovering valuable metals, particularly copper, from scrap cables and wires.

Its primary purpose is to process discarded cables into separate components, primarily metals and plastics, which can then be reused or sold. Here are the main uses and applications of a cable granulator:

Primary Uses of a Cable Granulator

Copper Recovery:

The most common use of a cable granulator is to recover copper from various types of cables and wires.

Copper is a valuable metal used in many industries, and recovering it from scrap can be economically beneficial.

Recycling Electrical Cables:

Electrical and electronic waste, such as old electrical cables, wiring harnesses, and power cords, can be processed to extract valuable metals and reduce landfill waste.

Processing Industrial Cables:

Industries generate large amounts of scrap cables from machinery, electrical systems, and equipment.

Cable granulators can process these industrial cables to reclaim metals and plastics.

Recycling Automotive Wiring:

Vehicles contain extensive wiring systems that, when scrapped, can be processed by cable granulators to recover copper and other metals from automotive wiring harnesses.

Handling Mixed Cable Types:

Cable granulators can process a wide range of cable types, including household wiring, telecommunication cables, power cables, and fiber optic cables, making them versatile tools in recycling operations.

Applications in Various Sectors

Recycling Facilities:

Cable granulators are widely used in recycling plants and facilities dedicated to processing electronic and electrical waste.

They help streamline the recycling process and maximize material recovery.

Scrap Metal Yards:

Scrap yards use cable granulators to process the mixed scrap cables they receive, separating valuable metals from the plastic insulation for sale and recycling.

Manufacturing Industry:

Manufacturing companies that generate scrap cables during production can use cable granulators to recycle in-house waste, reducing material costs and promoting sustainability.

Municipal Waste Management:

Municipal waste management systems can incorporate cable granulators to process electronic waste collected from households and businesses, reducing landfill waste and recovering valuable materials.

Environmental and Sustainability Initiatives:

Organizations focused on environmental protection and sustainability use cable granulators to promote recycling, reduce waste, and conserve natural resources by recovering metals from discarded cables.

Advantages of Using Cable Granulators

Economic Benefits:

Recovered copper and other metals can be sold, providing a revenue stream for recycling businesses and reducing the need for raw material extraction.

Environmental Impact:

Reduces the amount of electronic waste sent to landfills, minimizes environmental pollution, and conserves natural resources by recycling existing materials.

Efficiency and Productivity:

Automated and efficient processing of scrap cables increases productivity in recycling operations and reduces the need for manual labor.

Resource Conservation:

By recovering metals from scrap cables, cable granulators contribute to the conservation of natural resources and reduce the environmental footprint of manufacturing and disposal processes.

In summary, cable granulators are essential tools in the recycling industry, enabling the efficient and profitable recovery of valuable metals from a variety of scrap cables and wires.

They play a crucial role in promoting sustainability, reducing waste, and conserving natural resources.

How does a cable granulator work?

A cable granulator works through a multi-step process that involves shredding, granulating, and separating the components of scrap cables to recover valuable metals like copper.

Here’s a detailed breakdown of how the process works:

Step-by-Step Process of a Cable Granulator

Feeding

Scrap cables and wires are fed into the machine.

This can be done manually or through an automated feeding system depending on the size and design of the granulator.

Primary Shredding

The cables pass through a primary shredder, which cuts them into smaller, more manageable pieces.

This initial shredding makes it easier to handle and process the material in subsequent steps.

Granulation

The shredded cables are then fed into a granulator, which further reduces the size of the material into fine granules.

The granulator uses rotating blades to chop the cables into small pieces, typically a few millimeters in size.

Separation

After granulation, the mixture of metal and plastic particles is processed through various separation techniques to isolate the copper (or other metals) from the plastic insulation.

Common separation methods include:

Air Separation: An air separator uses airflow to separate lighter plastic particles from heavier metal particles.

Vibration Separation: A vibrating table or screen is used to separate materials based on density and particle size.

Magnetic Separation: For cables that may contain ferrous metals, a magnetic separator can be used to remove these metals from the mix.

Electrostatic Separation: An electrostatic separator charges the particles and uses an electric field to separate metals from non-metals based on their conductive properties.

Collection

The separated materials are collected in different bins or conveyors.

The metal granules, primarily copper, are collected for resale or further processing, while the plastic insulation is collected separately for recycling or disposal.

Dust Collection

Many cable granulators have built-in dust collection systems to capture and contain any dust generated during the shredding and granulating processes.

This helps maintain a clean working environment and minimizes airborne pollutants.

Diagram of the Cable Granulator Process

Input: Scrap cables → Shredder → Granulator → Separator (Air/Vibration/Magnetic/Electrostatic) → Collection (Copper granules, Plastic fragments) → Output.

Key Points in the Process

Efficiency: Modern cable granulators are designed to maximize efficiency, ensuring a high throughput and quick processing times.

Purity: The combination of different separation methods ensures a high purity of recovered metals, making them suitable for direct reuse in manufacturing.

Automation: Advanced granulators often feature automated systems that require minimal operator intervention, improving safety and productivity.

Benefits of the Process

Resource Recovery: Efficiently recovers valuable metals like copper, reducing the need for new mining and raw material extraction.

Environmental Protection: Reduces electronic waste and minimizes environmental pollution by recycling instead of discarding scrap cables.

Economic Value: Generates revenue from the sale of recovered metals and reduces costs associated with waste disposal.

By following these steps, a cable granulator effectively transforms waste cables into valuable raw materials, contributing to sustainability and economic efficiency in the recycling industry.

What is the benefit of cable granulator?

A cable granulator offers numerous benefits, particularly in the context of recycling and resource recovery.

Here are the key advantages:

Economic Benefits

1. Revenue Generation:

By recovering valuable metals like copper from scrap cables, businesses can sell these metals, creating a significant revenue stream.

The high purity of the recovered metals makes them suitable for direct reuse in manufacturing, often fetching good market prices.

2. Cost Savings:

Reduces the need to purchase raw materials, as recycled copper and other metals can be reused in production processes.

Lowers waste disposal costs, as less material is sent to landfills.

Environmental Benefits

1. Waste Reduction:

Cable granulators significantly reduce the volume of waste by transforming scrap cables into reusable raw materials.

Decreases the amount of electronic waste that ends up in landfills, mitigating environmental pollution.

2 Resource Conservation:

By recycling metals from cables, the need for mining and extracting new raw materials is reduced, conserving natural resources.

Supports the circular economy by keeping materials in use for longer periods.

3. Lower Carbon Footprint:

Recycling metals typically requires less energy compared to extracting and processing new metals, resulting in lower greenhouse gas emissions.

Operational Benefits

1. Efficiency and Productivity:

Modern cable granulators are designed for high throughput and can process large volumes of cables quickly, enhancing productivity.

Automation and easy-to-use controls reduce the need for manual labor, lowering operational costs and minimizing human error.

2. High Purity Output:

Advanced separation technologies (air, vibration, electrostatic) ensure that the recovered metals are of high purity, increasing their value and usability.

3. Versatility:

Cable granulators can handle a wide variety of cable types and sizes, from household wiring to industrial cables, making them versatile tools in recycling operations.

Safety and Compliance

1. Enhanced Safety:

Equipped with safety features like emergency stop buttons, protective covers, and dust collection systems, cable granulators provide a safer working environment.

Reduces the risk of injury from handling scrap cables manually.

2. Regulatory Compliance:

Helps businesses comply with environmental regulations by ensuring proper recycling and disposal of electronic waste.

Reduces potential legal and financial penalties associated with improper waste management.

Summary

A cable granulator provides significant economic, environmental, operational, and safety benefits.

By efficiently recovering valuable metals from scrap cables, it supports sustainable recycling practices, reduces waste, conserves resources, and generates revenue.

These advantages make cable granulators essential tools in the recycling industry, promoting both environmental responsibility and economic efficiency.

How many kilograms of copper can be produced in a day with a cable granulator?

The cable granulator is a device that crushes and sorts waste wires and cables into copper and plastic through a physical separation process.

Copper is in great demand in the market and has a large profit margin.

Therefore, for many potential customers, how much copper can be produced in a day with waste cable and wire granulator is a question they are very concerned about.

Today, we will analyze how many kilograms of copper can be produced in a day from three factors:

Cable granulator model, processed raw material types and cable granulator type

Cable granulator specifications

The larger the cable granulator specifications, the more waste wires and cables it can process, and the more copper and plastic it can process.

Currently, the processing capacity of a single cable granulator ranges from 100 kg to 2,000 kg.

We need to choose a suitable cable granulator model according to our actual situation to avoid the situation where there are too many raw materials and small equipment specifications, resulting in equipment overload or too few raw materials and large equipment specifications, resulting in equipment idleness.

Processing raw material types

There are many types of waste wires and cables, such as automotive wires, household square wires, electrical appliance wires, headphone wires, etc.

The copper output rate of the waste cable and wire granulator is also related to the copper content in the waste wires and cables.

For example: the copper content of automotive wires is 60%, the copper content of 2 square wires is 55%, and the copper content of 4 square wires is 70%.

When processing one ton 4 square wires, the copper output will be higher than that of the other two wires.

Cable granulator type

The cable granulator is divided into dry cable granulator and wet cable granulator.

The wet waste cable granulator adopts the water shaking table sorting method.

Water source needs to be continuously injected during the treatment process. The water flow will take away part of the copper, resulting in a lower copper yield.

The dry cable granulator adopts the physical separation sorting method.

No water or any chemical agents are added during the treatment process.

It adopts airflow specific gravity and high-voltage electrostatic double sorting, and the copper yield can reach 99%.

In general, the amount of copper can be produced in a day is affected by many factors.

Only by choosing the right equipment, rationally selecting the raw materials to be processed, and choosing a dry cable granulator can the copper yield be maximized.

Therefore, when waste wire and cable are processed, it is necessary to comprehensively consider the above factors to ensure that the equipment can achieve the maximum copper yield.