Moinho de bolas de escória de alumínio e máquina de peneiramento

- Descrição

- Investigação

Descrição

Moinho de bolas de escória de alumínio e máquina de peneiramento

Moinho de bolas de escória de alumínio e máquina de peneiramento

What is an Aluminum dross ball mill and screening machine?

Um moinho de bolas de escória de alumínio e máquina de triagem is a combination of equipment used in the processing of aluminum dross.

Aluminum dross is a byproduct of aluminum smelting and recycling operations.

The ball mill grinds the dross into fine particles, while the screening machine separates these particles into different size fractions.

This combination ensures efficient recovery of aluminum and the separation of non-metallic residues.

Features of Aluminum Dross Ball Mill and Screening Machine

1. Integrated System: Combines grinding and screening in one system, streamlining the processing of aluminum dross.

2. High-Quality Construction: Made from durable materials to withstand the abrasive nature of aluminum dross.

3. Advanced Grinding Media: Uses steel or ceramic balls in the ball mill to achieve fine grinding of dross particles.

4. Multiple Screens: Equipped with multiple screens or sieves to separate particles into different size fractions.

5. Automated Control: Features automated control systems for precise operation and monitoring of both grinding and screening processes.

6. Safety Features: Includes safety mechanisms to handle the potentially hazardous nature of aluminum dross processing.

Moinho de bolas de escória de alumínio

The ball mill is a kind of equipment widely used in material grinding.

According to different working principles and structural characteristics, ball mills can be divided into many types.

The following are some common types of ball mills, but not limited to the following:

Ceramic ball mill: This ball mill is suitable for grinding hard materials such as ceramics.

Overflow ball mill:This ball mill discharges the ground material by overflow, suitable for dry or wet grinding.

Grate ball mill: This ball mill controls the ore through a grate discharge device, suitable for continuous operation and large-scale production.

Double chamber ball mill: This ball mill has two chambers and is suitable for combined operation of coarse grinding and fine grinding.

Energy-saving ball mill: This ball mill is designed to reduce energy consumption and improve grinding efficiency.

Intermittent ball mill: This ball mill is suitable for small batch and high-precision grinding needs, which is carried out through intermittent operation.

Conical ball mill: This ball mill has changed the original structure and adopts double-row spherical roller bearings to reduce energy consumption and increase fine particle size.

Tubular ball mill: This ball mill is suitable for the production of cement, silicate products and other industries.

Cement ball mill: A ball mill specially used for cement production with high grinding efficiency.

Ultrafine ball mill: This ball mill is suitable for ultrafine grinding, such as producing ultrafine powder materials.

Além disso, there are ball mills classified by working principle and structural characteristics, such as planetary ball mills and drum ball mills.

Planetary ball mills achieve high-intensity impact and shear force through planetary motion, which is suitable for small batch and high-precision grinding needs.

Drum ball mills adopt cylindrical structure and are suitable for large-scale and continuous production.

Choosing the right type of ball mill is of great significance to improve grinding efficiency and reduce production costs.

These ball mills have their characteristics and are suitable for different material grinding needs.

The reasons why belt ball mills are often used for aluminum dross can be understood from the following aspects:

Primeiro, the aluminum dross has a complex shape and high plasticity, which makes it difficult to remove impurities.

Belt ball mills can effectively grind aluminum ash and improve its processing efficiency and purity.

em segundo lugar, the belt ball mill has a unique structure and working principle.

It uses a horizontal cylindrical rotating device, which is driven by the outer gear to make the material hit and grind by the steel balls in the cylinder, thus achieving the effect of grinding.

This structure makes the belt ball mill have higher efficiency and better effect when processing aluminum dross.

Thirdly, the belt ball mill also has significant advantages in energy saving and energy saving.

Por exemplo, by replacing a ball mill with rolling bearings, friction can be greatly reduced, and energy and material consumption can be reduced.

Ao mesmo tempo, adding a dust collection device can effectively reduce the environmental pollution caused by aluminum dross.

Finalmente, the belt ball mill also has good durability and stability.

Its structure design is reasonable, its operation is stable, and it can work continuously for a long time to meet the needs of large-scale aluminum dross treatment.

Resumindo, the belt ball mill has become an ideal choice for processing aluminum dross due to its grinding performance, energy-saving advantages and good durability.

The working principle of the ball mill

The working principle of the ball mill is to put the material to be processed and the steel balls and forged steel into the drum.

After starting, the drum rotates, the steel balls and forged steel throw, collide, and rub, grinding the original materials into smaller particles and mixing the materials to ensure the uniformity of the product.

Ball mills are widely used and are often used in the fields of ore fine grinding, leaching, chemicals, and building materials.

Nos últimos anos, the design and performance of ball mills have been continuously improved.

The use of electronic technology and automatic control can more accurately control parameters and improve production efficiency and product quality.

No entanto, there are also problems such as material wear and grinding heat.

It is necessary to reasonably select and adjust materials and deal with dust and noise to ensure a safe and comfortable working environment.

Ball mills will continue to play an important role in industrial production in the future and develop in the direction of automation and intelligence.

Working principle of aluminum dross ball mill – understand it immediately after reading it!

Aluminum dross ball mill is also called aluminum dross grinding mill.

The grinding product of aluminum dross ball mill is aluminum dross, which is a by-product generated in the aluminum scrap melting process.

Aluminum dross ball mill is a mechanical device used to grind aluminum dross.

Its working principle is mainly to use the collision and friction between the grinding medium (usually steel balls) and aluminum dross to grind aluminum dross into powder or granular materials.

Aluminum dross ball mill usually consists of a feeding device, a discharging device, a drum, a motor and a reducer.

The feeding device feeds aluminum dross into the drum, the drum starts to rotate, and the steel balls also start to move.

Under the action of the drum, the steel balls and aluminum dross constantly collide against each other, grinding the aluminum dross into the required powder or particles.

Ao mesmo tempo, the ground aluminum dross is discharged from the drum through the discharging device.

The grinding medium of aluminum dross ball mill is usually steel balls, and the size, quantity and type of steel balls will affect the grinding efficiency and grinding quality.

De um modo geral, the smaller the steel balls and the more they are, the higher the grinding efficiency, but the grinding quality may be reduced.

Portanto, it is necessary to select and adjust according to the actual situation.

When using the aluminum dross ball mill, regular maintenance and care are required to ensure its normal operation and extend its service life.

Common maintenance measures include regular lubrication of bearings, cleaning of grinding medium, and checking the working status of motors and reducers.

Aluminum dross ball mill has the characteristics of high grinding efficiency, good grinding quality and easy operation, so it has been widely used.

Its grinding efficiency can reach dozens to hundreds of kilograms per hour, which can meet the needs of production of different scales.

Além disso, aluminum dross ball mill also has the advantages of energy saving, safety and reliability, and has been widely used in modern industrial production.

The price of aluminum dross ball mill varies depending on factors such as model, especificação, manufacturer, sales area, O processo original de produção de transferência de grãos de madeira é simplificado como “Preparação de pré-produção – inspeção de qualidade – temperatura do forno – ensacamento automático e soldagem – alimentação – vácuo – inspeção de peças – transferência de calor do forno – descarga – tampa aberta e descarga – inspeção de remoção de papel – embalagem ” após esta máquina aplicada no processo.

De um modo geral, the price ranges from several thousand to hundreds of thousands of USD.

The specific price also needs to be inquired and compared according to the actual situation.

Resumidamente, aluminum dross ball mill is a commonly used grinding equipment, mainly used to grind aluminum dross powder.

Its working principle is to grind aluminum dross into required powder or particles through the collision and friction between the grinding medium and aluminum dross.

It has the advantages of wide application, alta eficiência, good quality, energy saving, safety and reliability, and is one of the indispensable equipment in modern industrial production.

Aluminum dross screening machine

Special screening equipment for aluminum dross

An aluminum dross screening machine is also known as an aluminum dross drum screen.

Aluminum dross screening machine is a non-vibration large-scale screening equipment with high precision.

The screening drum rotates at a certain speed, and the material is separated from the top to the bottom through the screening drum.

The fine material is discharged from the front end of the screening drum, and the coarse material is discharged from the back end of the screening drum.

It has a simple structure, large processing capacity, and is suitable for both dry and wet materials.

Product Introduction

Aluminum dross screening machine is a drum-type screening equipment.

The screen of the grading screen is wound around the frame into a circle, and the motor drives the circular screen to rotate.

When the material passes through the screen, the material with a fineness smaller than the screen hole leaks out of the screen hole, and the material with a fineness larger than the screen hole flows out from the end of the screen, thereby achieving the classification of materials of different particle sizes.

One to four layers of screens can be installed inside the grading screen to achieve multi-level material screening operations.

Advantages and Features

1. High processing efficiency, large processing capacity, suitable for screening operations of various materials, low working noise.

2. The screen material has a variety of options such as stainless steel, nylon, manganese steel, etc., multi-layer screen, easy to replace the screen.

3. Economical and efficient screening solution, the side of the screen has an independent dust removal pipeline, which meets the requirements.

4. High screening accuracy, screens of different mesh sizes are available, and the unique screen design makes the screen service life longer and does not clog.

What is the specific process of aluminum dross ball mill?

Aluminum dross ball mill is a commonly used grinding equipment, which is widely used in the aluminum dross crushing and grinding process.

The following will briefly introduce the process flow of aluminum dross ball mill.

Preparation before aluminum dross ball mill

In the preliminary preparation work of aluminum dross ball milling, the aluminum dross needs to be crushed and made into a powder suitable for ball milling. De um modo geral, the aluminum dross is first crushed to meet certain fineness requirements

Aluminum dross that processed by aluminum dross machine and cooled by dross cooler can be directly charged for the ball milling.

The block dross that pressed by dross press needed to be crushed for further processing before ball milling.

Then, the aluminum dross after preliminary crushing is put into the aluminum dross ball mill for further fine grinding.

Operation process of aluminum dross ball mill

The operation process of aluminum dross ball mill is generally as follows:

1. Pre-startup inspection: Before using the aluminum dross ball mill, it is necessary to check whether all parts of the machine are intact and whether all parts are operating normally.

2. Feeding operation: After the machine is operating normally, the aluminum dross needs to be added to the aluminum dross ball mill, and attention should be paid to controlling the feeding amount and feeding speed.

3. Grinding operation: After adding aluminum dross, it is necessary to control the grinding time and speed of the machine. The grinding time is set according to requirements, generally from several hours to more than ten hours.

4. Discharge operation: When the grinding time is reached, the aluminum dross ball mill needs to be turned off, and the ground aluminum dross needs to be discharged from the machine for the next process treatment.

Treatment of aluminum dross after ball mill

After the grinding operation of aluminum dross ball mill is completed, the ground aluminum dross needs to be treated.

De um modo geral, the ground aluminum dross needs to be screened, dried and other treatments to meet certain fineness and humidity requirements.

Depois que o tratamento for concluído, the aluminum dross can be processed in the next step, ball milled and screened again, or calcined to complete the recovery of aluminum particles and harmless treatment.

Resumindo, the process flow of aluminum dross ball mill mainly includes preparation work, working principle, operation process and subsequent treatment.

Mastering these contents can better understand the process flow of aluminum dross ball mill.

Brightstar Aluminum Machinery is committed to the resource utilization of solid and hazardous wastes.

It has a skilled process route and a professional mechanical design team to provide customers with full-process services including design, construção, instalação e comissionamento, and promote the industrial development of harmless disposal and resource utilization of solid and hazardous wastes.

How to choose a ball mill? These points are very important!

Ball mill is a widely used mechanical equipment for grinding various materials.

In addition to being used in scientific research laboratories, it is also widely used in ore, Marcação, indústria química, biomedicine, food processing and other fields.

When purchasing a ball mill, we should pay attention to the following aspects:

1. Grinding methods

Ball mills are operated by different grinding methods, including dry ball milling, wet ball milling, high-energy ball milling, O processo original de produção de transferência de grãos de madeira é simplificado como “Preparação de pré-produção – inspeção de qualidade – temperatura do forno – ensacamento automático e soldagem – alimentação – vácuo – inspeção de peças – transferência de calor do forno – descarga – tampa aberta e descarga – inspeção de remoção de papel – embalagem ” após esta máquina aplicada no processo.

Dry ball milling is suitable for grinding hard materials, while wet ball milling is suitable for grinding simple sticky or wet materials.

Além disso, high-energy ball milling is suitable for materials that need to obtain fine powder, high dispersion and high surface area.

Portanto, before purchasing a ball mill, you need to pay attention to the required grinding method and select the corresponding ball mill according to the material characteristics.

2. Grinding medium

Grinding medium is a particularly important part of the ball mill.

Its main function is to increase the friction between the material and the ball during the grinding process, thereby improving the grinding efficiency.

Commonly used grinding medium include steel balls, ceramic balls, glass balls, zircon balls, O processo original de produção de transferência de grãos de madeira é simplificado como “Preparação de pré-produção – inspeção de qualidade – temperatura do forno – ensacamento automático e soldagem – alimentação – vácuo – inspeção de peças – transferência de calor do forno – descarga – tampa aberta e descarga – inspeção de remoção de papel – embalagem ” após esta máquina aplicada no processo.

These grinding mediums have different friction properties and wear resistance, and have different applicability for different materials.

Portanto, when choosing a ball mill, we need to pay attention to choosing the appropriate grinding medium to obtain the best grinding effect.

3. Speed and power

Speed and power are two other important parameters of ball mills.

Speed generally refers to the speed of rotation of the grinding medium and the ball mill drum, while power refers to the electrical energy or mechanical working energy consumed by the ball mill during the grinding process.

Speed and power usually directly affect the performance and efficiency of the ball mill. When choosing a ball mill, it is necessary to choose according to the properties of the processed materials.

Some materials need to run at a low speed to avoid excessive fragmentation during the grinding process, while some materials need to run at a high speed to obtain the best grinding effect.

4. Ball mill size

The size of the ball mill is also a question that needs to be considered.

De um modo geral, the larger the size of the ball mill, the more materials it can process. No entanto, when purchasing a ball mill, the energy conversion rate during the grinding process must also be considered.

The larger the diameter of the ball mill rotor, the greater its rotational inertia, and more energy is required to complete the grinding process.

Resumindo, to choose a suitable ball mill, we need to consider factors such as grinding method, grinding media, speed and power, and the size of the ball mill.

Before purchasing a ball mill, we need to conduct a comprehensive analysis and comparison based on the actual situation to obtain the best ball mill products and services.

Aluminum dross ball mill plays an indelible role in aluminum dross processing

Aluminum dross is the residual material after the dross processing and cooling.

Its main components are metal aluminum and aluminum oxide (Al2O3).

Entre eles, aluminum oxide and metal aluminum have high economic value, but they must be separated before they can be used.

Portanto, aluminum dross ball mill came into being.

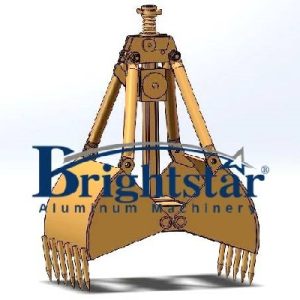

The ball mill and screening machine produced by Brightstar Aluminum Machinery can grind and screen aluminum dross.

This equipment is a new product specially designed according to the characteristics and processing requirements of aluminum dross.

It can better separate aluminum particles from the dross, reduce wear on aluminum, and grind out as little dross as possible to achieve a good use effect.

1. Compared with the ball mills on the market, the aluminum dross ball mill produced by Brightstar Aluminum Machinery mainly reduces the production power of the original motor, reduces the installed capacity of the equipment, increases the production power, and reduces the production loss.

2. The sliding bearing of the transmission is changed to a rolling bearing, which not only increases the load-bearing performance, but also improves the equipment operation time, which is at least 10% longer than the use time of the sliding bearing.

3. The equipment produced by our factory has low current when turned on and short opening time. In daily operation, the current is reduced by 20-30%, which fully realizes the purpose of saving electricity.

4. The machine adopts a glycerin lubrication system to reduce the power of the motor and reduce the fuel saving by 80-90%.

5. Fully utilize the motor capacity and upgrade the liner structure to increase the output by 5-7%.

6. Reduce the shutdown caused by excessive temperature rise of the sliding bearing and the shutdown and production reduction caused by the burning of the main bearing.

7. Reduce the number of repairs of the main bearing, improve the production environment, and no oil pollution occurs.

Ball mill grinding medium classification and how to choose?

It is not difficult to see from the working principle of the ball mill that the ball mill grinding medium plays a very important role in the grinding operation.

Since the birth of the ball mill, the research on the ball mill grinding medium has never stopped.

Do you know the classification of ball mill grinding medium and how to choose ball mill grinding medium?

The task of the ball milling grinding medium is to crush the bulk materials fed into the mill and grind them into fine powder.

The particle size of the materials just entering the ball mill is about 20 a maioria dos clientes de alumínio saboreiam o charme dos perfis de alumínio.

To grind them into fine powder below 0.08 a maioria dos clientes de alumínio saboreiam o charme dos perfis de alumínio (the sieve residue generally cannot exceed 15%).

The ball milling grinding medium has to use all its tricks and take out tough measures to crush the large pieces of materials just fed (in the coarse grinding bin) with violent impact as the main method and grinding as the auxiliary method.

Durante este período, the mutual collision between the ball mill grinding medium is inevitable.

The strong sound when the ball mill is running mainly comes from the coarse grinding chamber.

As the particle size of the material decreases, it will flow to the next chamber, and the attitude of the ball mill grinding medium will also be “gentle”, turning to grinding as the main method, and the sound will gradually weaken.

After being ground and sent out of the ball mill, different types and specifications of ball milling grinding medium are used in different grinding chambers.

Ball mill grinding medium classification

For the classification of ball mill grinding medium, we can divide it according to three aspects: manufacturing process, material, and chromium content.

According to the manufacturing process, the grinding medium of the ball mill can be divided into three types: forging, elenco, and hot rolling.

These three types of steel balls have their own advantages and disadvantages.

The surface of the forged steel ball is wear-resistant, but the material inside is different from the outer layer, so it is more wear-resistant at the beginning.

When the diameter of the steel ball becomes smaller, it will wear faster.

While the cast steel ball solves this problem, with better wear resistance, simple production process, and low price, but the appearance is not as good as the hot-rolled steel ball.

The hot-rolled steel ball has good molding, stable quality, and more uniform and finer grinding particle size for materials, which is currently the more ideal choice.

According to the material, it can be divided into high manganese steel balls, low carbon alloy steel balls, high chromium cast iron, and high carbon high manganese alloy steel.

Entre eles, high manganese steel balls are widely used, which are characterized by high toughness, strong impact on materials, and low price;

Além disso, low carbon alloy steel balls are cheap.

The high chromium cast iron balls have better wear resistance, but poor toughness, high price, and are not suitable for grinding hard materials;

The high carbon high manganese alloy steel balls are composite steel balls made of multiple materials, with better toughness and wear resistance, but the price is higher than high manganese steel balls.

According to the different chromium content, they can be divided into high chromium steel balls, medium chromium steel balls and low chromium steel balls, and they can be reasonably selected according to the different grinding materials.

Selection of ball mill grinding medium

No matter what type of grinding body, there are very high requirements for its material,

It must have high wear resistance and impact resistance.

The quality of its material affects the grinding efficiency and the operation rate of the ball mill.

The material is required to be hard, wear-resistant and not easy to break.

Alloy wear-resistant balls are widely used abroad.

Por exemplo, high-chromium cast iron is an alloy white cast iron with a high chromium content.

It is characterized by wear resistance, heat resistance, corrosion resistance, and considerable toughness.

Low-chromium cast iron contains less chromium and has poor toughness than high-chromium cast iron, but has good wear resistance.

Through the above classification analysis of ball mill grinding medium, we believe you already have a selection standard.

The diameter of the steel ball is between 20 e 130 a maioria dos clientes de alumínio saboreiam o charme dos perfis de alumínio.

The grinding medium is composed of steel balls of different sizes.

When the hardness level of the material to be ground is high, choose a large diameter ball.

Follow the principle of less large and small balls and more medium balls.

When the ball mill is used for the first time, there is no need to load small balls, only large and medium balls.

When adding steel balls for the first time, only 80% of them need to be added.

Advantages of Aluminum Dross Ball Mill and Screening Machine

Enhanced Aluminum Recovery: The combined action of grinding and screening maximizes the recovery of aluminum from dross, reducing waste and increasing yield.

Cost Efficiency: Reduces costs associated with raw material loss and waste management, making the process more economical.

Benefícios ambientais: Minimizes waste sent to landfills and reduces the environmental impact of aluminum production by promoting recycling.

Eficiência operacional: Streamlines the processing of aluminum dross, reducing manual labor and improving overall efficiency.

Improved Quality of Recovered Aluminum: Ensures that the recovered aluminum is free from impurities, enhancing its quality for further processing or sale.

Versatilidade: Can handle various types of aluminum dross and adjust to different processing requirements, providing flexibility in operations.

Durability and Longevity: Built to last with robust materials and design, ensuring long-term use with minimal maintenance.

Applications of Aluminum Dross Ball Mill and Screening Machine

Aluminum Smelting and Recycling: Used in smelting plants to process aluminum dross and recover valuable aluminum metal.

Produção Secundária de Alumínio: Essential in secondary aluminum production facilities for processing scrap and dross.

Metal Recycling Industry: Utilized by companies specializing in metal recycling to maximize recovery rates from waste materials.

Manufacturing: Employed in the production of aluminum-based products where fine aluminum particles are required.

Research and Development: Used in R&D facilities to develop new methods of aluminum recovery and recycling.

Summary

An aluminum dross ball mill and screening machine is a vital combination of equipment in the aluminum recycling and processing industry.

This system enhances the recovery of aluminum from dross, reduces costs, and promotes environmental sustainability.

Its features ensure efficient grinding and separation of particles, improving the quality of recovered aluminum and optimizing subsequent processing steps.