அலுமினியம் வெளியேற்றும் அச்சு பிரித்தெடுக்கும் இயந்திரம்

- அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ்

- அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ்

அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ்

அலுமினியம் வெளியேற்றும் அச்சு பிரித்தெடுக்கும் இயந்திரம்

அலுமினியம் வெளியேற்றும் அச்சு பிரித்தெடுக்கும் இயந்திரம்

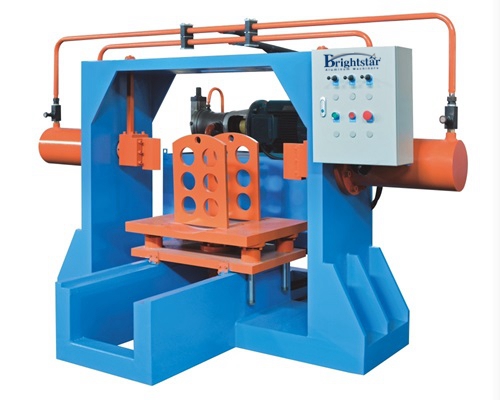

An aluminum extrusion mold disassembly machine, also known as die disassembly machine, uses a hydraulic device to separate the mandrel and die cap of the aluminum extrusion mold.

Automatic mold disassembly machine, reduce the labor intensity of workers, and improve production efficiency.

It is suitable for the separation operation of the mandrel and die cap of the aluminum extrusion mold in the aluminum profile manufacturing industry.

Compared with the current manual hammering mold disassembly method commonly used in the industry, the application of this machine can greatly improve the efficiency of mold disassembly, reduce the labor intensity of workers, and the mold disassembly process is safe, stable and efficient, and can well avoid manual mold disassembly can cause injuries to people and molds due to workers’ careless or fatigued operations.

It is indispensable and ideal equipment for standardizing safe production procedures in the aluminum profile processing and manufacturing industry.

In order to effectively improve the production capacity of the mold disassembly machine, the equipment uses a loading device to lift the mold, a flat roller to transport the mold, an automatic positioning and separation mold, and an automatic conveying platform to output the mold.

Each process (loading, mold disassembly, discharging) can be carried out at the same time, effectively improving production efficiency.

The mold disassembly process is safe, stable and efficient.

A high degree of automation, superior operating environment and high production efficiency.

அம்சங்கள்

1.Reduce work-related injuries:

The common practice is to use a sledgehammer to hit the chisel with gravity to separate the mold.

During the process, small iron filings often fly into the arms or legs, causing work-related injuries. Using an automatic mold disassembly machine can avoid work-related injuries.

2. Reduce workers’ labor intensity:

An automated aluminum extrusion mold disassembly machine improves the working principle and changes the previous hard-working working environment.

3.Reduce the turnover rate of workers in the position:

கடந்த காலத்தில், people in this position needed to have the force, இல்லையெனில், they could not do the job, and the turnover of personnel was very high.

With the use of automated equipment, workers can work easily and efficiently with only mechanized workers, ensuring the stability of job personnel.

முக்கிய தொழில்நுட்ப அளவுரு

|

அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ் |

BS500 |

|

Max disassembly force |

380 kN |

|

Max working pressure |

21 MPa |

|

Diameter of mold |

Φ160 ~ Φ500 mm |

|

Max height |

360 அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ் |

|

Minimum gap depth of mold |

10 அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ் |

|

The gap width of mold |

4 அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ் |

|

Height of stop pin |

25 அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ் |

|

மொத்த சக்தி |

(7.5+2.2)KW |

|

சக்தி |

380 V |

|

திரும்பும் வேகம்: L*W*H |

2000 × 1200 × 2200 அலுமினிய ஸ்கிராப் ப்ரொப்பல்லர் பிரஸ் |

|

எடை |

3500 kg Approx. |

It can be customized according to the parameters provided by the customer.

This parameter is a conventional configuration.

The actual parameters of the equipment are subject to the customer’s request.

The situation of disassembly and assembly of mold

The aluminum extrusion die is a type of forming die.

Its discharging method is achieved by extrusion process.

It is widely used in aluminum special-shaped structures.

When working, the aluminum extrusion die is placed at the front end of the extruder, used for extrusion shaping of aluminum profiles.

During the assembly, debugging, and maintenance of aluminum extrusion molds, it is usually necessary to disassembly and assembly the mandrel and die cap of the aluminum extrusion mold multiple times.

தற்போது, manual operations are mostly used to disassembly and assembly the aluminum extrusion mold.

When disassembly the mold, the parting line of the aluminum extrusion mold is manually struck with a pushing stick and a hammer, so that the mandrel of the aluminum extrusion mold is It is separated from the die cap.

When assembling the mold, the mandrel and die cap of the aluminum extrusion mold are struck with a hammer to assemble the mold.

Disassembly and assembly of the mold in this way are labor-intensive and low-efficiency, and the aluminu extrusion mold product is easily damaged during the knocking process.

After years of research and development, we have developed a mold disassembly and assembly machine with a novel structure, which is accurate and reliable, and has high efficiency and strong stability.

It replaces manual operation and achieves rapid mold disassembly and assembly.

It can meet the mold disassembly or assembly of aluminum extrusion molds with different diameters and sizes.

It includes a base device, a power device, a mold disassembly and assembly device and a control system device.