ஒரு அலுமினியம் டிராஸ் இயந்திரம் மூலம் உங்கள் செயல்முறையை புரட்சி செய்யுங்கள்

ஒரு அலுமினியம் டிராஸ் இயந்திரம் மூலம் உங்கள் செயல்முறையை புரட்சி செய்யுங்கள்

ஒரு அலுமினியம் டிராஸ் இயந்திரம் மூலம் உங்கள் செயல்முறையை புரட்சி செய்யுங்கள்

In the modern aluminum industry, செயல்திறன் மற்றும் நிலைத்தன்மை மிக முக்கியமானது. நிறுவனங்கள் தங்கள் செயல்பாடுகளை மேம்படுத்தவும், கழிவுகளை குறைக்கவும் முயல்கின்றன, மேம்பட்ட தொழில்நுட்பத்தின் ஒருங்கிணைப்பு ஒரு முக்கியமான உத்தியாக மாறியுள்ளது.

One such technological advancement is the aluminum dross recycling machine, which has revolutionized the way aluminum dross is processed and utilized.

This article delves into the transformative impact of these machines, exploring how they work, their benefits, and their specifications.

Understanding Aluminum Dross

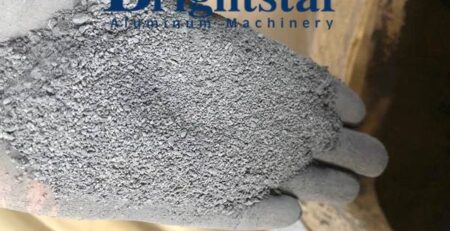

Aluminum dross is a byproduct formed during the smelting process of aluminum.

It consists of aluminum oxide, aluminum metal, and other impurities.

Traditionally, handling and processing this dross was labor-intensive and inefficient, leading to significant material losses and environmental concerns.

எனினும், the advent of the industrial aluminum dross machine has changed the game, providing a more efficient and eco-friendly solution.

How Does an Aluminum Dross Machine Work?

To comprehend the revolutionary nature of these machines, it is essential to understand how does an aluminum dross machine work.

The process begins with the collection of aluminum dross from the surface of molten aluminum generated from the aluminum melting furnace.

This dross is then fed into the machine, where it undergoes several stages of processing.

Stirring and processing: The initial stage involves mechanical stirring to separate aluminum from the dross. Use the residual heat from the dross, and make the full stirring, the aluminum metal can be extracted from the dross because of the gravity difference.

Separating: தி aluminum dross separation machine will separate 90% குப்பையிலிருந்து அலுமினியம். The liquid aluminum will flow from the bottom of the aluminum dross machine and the dross will be discharged from the backside of the dross machine.

Cooling: Once separated, the hot dross will be quickly cooled with the dross cooler. This step is crucial to prevent oxidation and preserve the quality of the recovered aluminum.

Collection and Storage: Finally, the processed aluminum is collected and stored for further use. The residual waste is also handled appropriately, minimizing environmental impact.

Benefits of Aluminum Dross Machine

தி benefits of aluminum dross machine are manifold, making it an indispensable tool for modern aluminum manufacturers.

Enhanced Recovery Rates: These machines significantly increase the recovery rate of aluminum from dross. By efficiently separating aluminum from impurities, manufacturers can reclaim more aluminum, reducing waste and boosting profitability.

Environmental Sustainability: By maximizing aluminum recovery and minimizing waste, these machines contribute to environmental sustainability. The reduced need for raw aluminum extraction lowers the industry’s carbon footprint.

செலவு சேமிப்பு: With higher recovery rates and reduced waste, companies can achieve substantial cost savings. The initial investment in an aluminum dross machine is often offset by the long-term financial benefits.

Improved Safety: Automating the dross processing reduces the exposure of workers to hazardous materials and high temperatures, enhancing workplace safety.

Consistency and Quality: These machines ensure consistent processing quality, resulting in high-purity recovered aluminum that meets industry standards.

Aluminum Dross Machine Specifications

When considering the integration of these machines into their operations, manufacturers must pay close attention to aluminum dross machine specifications.

Key specifications to consider include:

Processing Capacity: The volume of dross the machine can handle per hour.

Recovery Rate: The percentage of aluminum recovered from the dross.

Energy Consumption: The amount of energy required for operation.

Footprint: The physical size of the machine and its compatibility with existing facilities.

Automation Level: The extent to which the machine automates the dross processing steps.

The Role of Industrial Aluminum Dross Machines

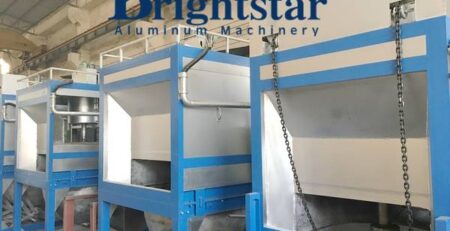

Industrial aluminum dross machines play a pivotal role in modern aluminum production. These machines are designed to handle large volumes of dross efficiently, making them ideal for high-capacity production environments.

They are equipped with advanced features such as real-time monitoring, predictive maintenance, and integration with other industrial systems, ensuring seamless operation and minimal downtime.

Technological Advancements in Dross Processing

The field of dross processing has seen significant technological advancements in recent years.

Innovations such as real-time monitoring, predictive maintenance, and integration with other industrial systems have made these machines more effective and reliable than ever before.

Future developments are likely to focus on further enhancing efficiency, reducing energy consumption, and minimizing environmental impact.

Case Studies: Real-World Applications

Numerous companies have successfully integrated aluminum dross machines into their operations, reaping substantial benefits.

For instance, a leading aluminum ingot producer Huihuang Metal reported a 25% increase in aluminum recovery rates and a 30% reduction in processing time after adopting an aluminum dross recycling machine.

Another aluminum extrusion company Foshan Honstar Aluminum Products Co., Ltd highlighted the improved safety and reduced environmental impact as significant advantages of their new dross processing system.

Future Trends in Aluminum Dross Processing

The future of aluminum dross processing looks promising, with several emerging trends set to shape the industry.

These include the development of more compact and energy-efficient machines, the integration of artificial intelligence for predictive maintenance and process optimization, and the increased use of eco-friendly materials and processes.

முடிவுரை

In conclusion, the integration of an Automatic Aluminum Dross Machine into aluminum production processes offers numerous benefits.

These machines enhance recovery rates, improve safety, செலவுகளை குறைக்க, and contribute to environmental sustainability.

By understanding how does an aluminum dross machine work and considering the relevant specifications, manufacturers can revolutionize their operations, achieving greater efficiency and profitability.

The ongoing technological advancements in this field promise an even brighter future for aluminum dross processing, making it an essential investment for any forward-thinking aluminum producer.