The factors that affect oxidation loss in aluminium melting

The factors that affect oxidation loss in aluminium melting

The factors that affect oxidation loss in aluminium melting

Here are the factors that affect oxidation loss in aluminium melting

1. The oxidation loss degree depends on the affinity between metal and oxygen and the metal surface oxidation film property

The affinity between aluminum and oxygen is big, but oxidation film α >1, so the oxidation loss is not too much.

In the melting, the surface-active elements that have a good affinity with oxygen will be oxidized in the first priority, or be oxidized with the base metal at the same time.

In this process, the property of alloy elements oxides and base metal oxides will control the whole alloy oxidation process.

2. Melting temperature

The effect law for melting temperature is metal oxidation speed is small as the temperature is low, the oxidation will speed up in the high temperature.

Because the diffusion of the material will augment in high temperature, the oxidation film temperature decrease, the linear expansion difference between oxidation film and metal increase, so the oxidation film will break.

3. The property difference of furnace gas has a different effect on oxidation loss

As the melting furnace structure, heating source and fuel-burning degree are different, there is a different proportion of O2, H2O, CO2, CO, H2, CmHn, SO2, N2, etc gas in the furnace gas, whether these gases make the metal oxidized or not is subject to the interaction between furnace gas and metal.

4. Aluminum melting furnace type

Different types of aluminum melting furnaces will affect oxidation loss in the melting.

As different melting furnace types, their molten pool, area, and heating mode will be different.

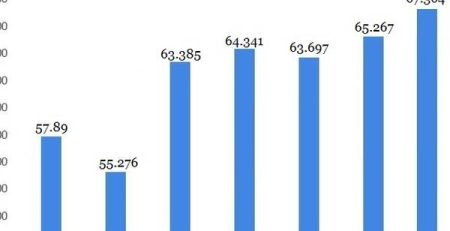

For example, in low frequency (LF) induction furnace melt aluminum alloy, the oxidation loss will be 0.4%-0.6%, electric resistance reverberatory oxidation loss is 1.0%-1.5%, flame furnace oxidation loss is 1.5%-3.0%.

5. Furnace charging, furnace feeding materials

Furnace charging condition is one important and considerable factor that affects oxidation loss.

The smaller the furnace charging lump, the bigger area will be, the oxidation loss will be more serious.

In general, aluminum ingot burning loss will be 0.8%-2.0%; the baled sheet scraps burning loss is 3%-10%, chipping scraps maximum burning loss can reach 30%.

6. In the fixed other conditions, the longer the melting time, the much more oxidation loss will be.

The above are the factors that affect oxidation loss in aluminium melting.

Brightstar Aluminum Machinery offers aluminium scrap melting and casting and aluminium dross recovery solution.

Contact us now to get a no-obligation quote on aluminium scrap melting and aluminium dross recovery!